GPR

Active Member

The owner Chris is serving in Iraq until April. He thought he had bought a good body until it came back from the media blaster. Someone had repaired the rust with fiberglass mat.

It was hard to leave his son. This is what we started with when I picked it up last April

After it was media blasted

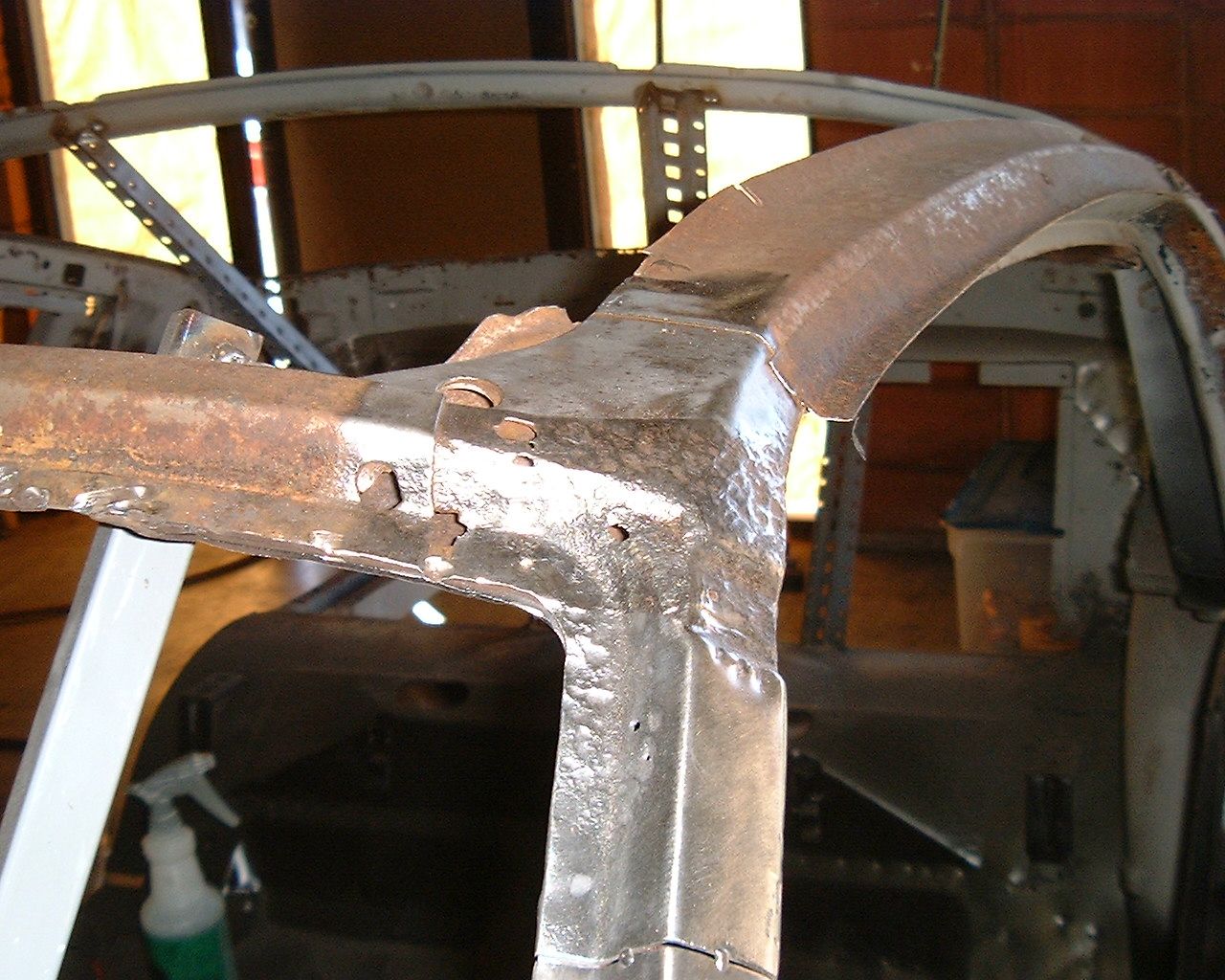

We decided to start in the front and work our way back. Someone had replaced the front fender apron but they just welded it in very few places over part of the old one. Brian my son removed it cleaned up it up and reattached it.

Brian welded the shock towers

Epoxied the front end with SPI epoxy

It was hard to leave his son. This is what we started with when I picked it up last April

After it was media blasted

We decided to start in the front and work our way back. Someone had replaced the front fender apron but they just welded it in very few places over part of the old one. Brian my son removed it cleaned up it up and reattached it.

Brian welded the shock towers

Epoxied the front end with SPI epoxy

Last edited by a moderator: