AzPete

Well-Known Member

"GPR" said:He is wearing gloves. I guess I won't post anymore action pictures.

no...no...no...keep them coming....interesting build.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

Hello there guest and Welcome to The #1 Classic Mustang forum!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

"GPR" said:He is wearing gloves. I guess I won't post anymore action pictures.

Brian is a master bodyman, and knows what he is doing. Other people on the forum are not that proficient and knowledgeable, and may not be aware of some concerns while welding. It's a case of "your mileage may vary"."GPR" said:He is wearing gloves. I guess I won't post anymore action pictures.

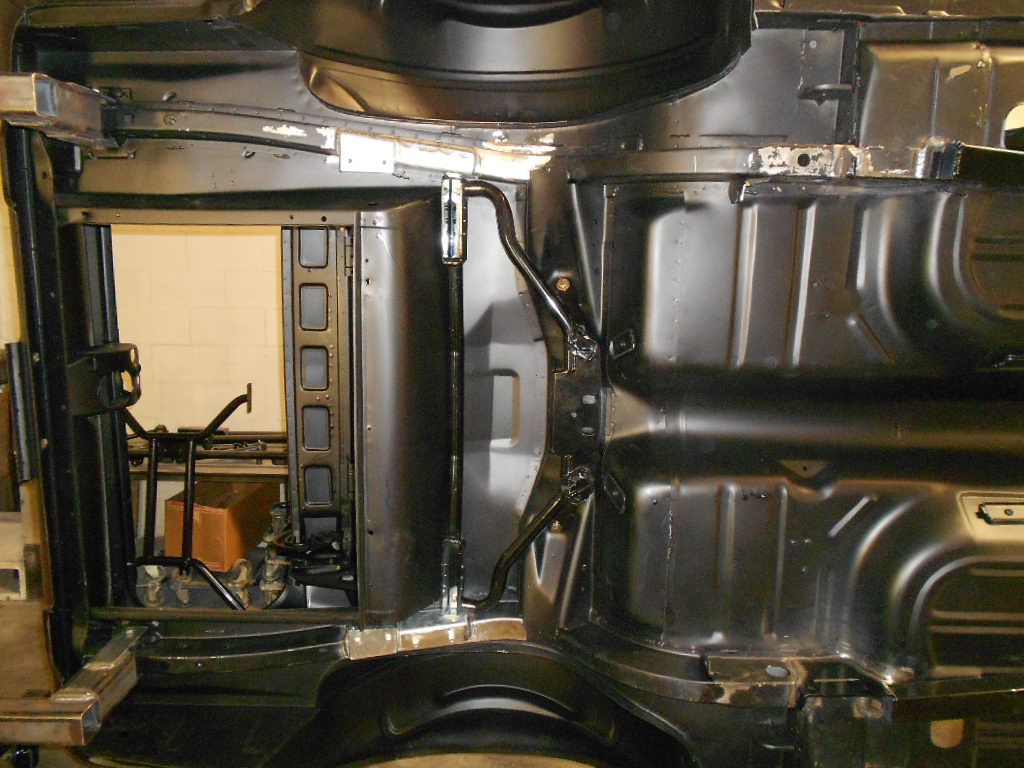

"GPR" said:Brian decided to improving the welding a little.

"guruatbol" said:Would the hood be too wide on an original car?

Sent from my DROID X2 using Tapatalk 2

"67 Fastback" said:Rusty, do you mind to post some more pics of how you added or clearance the hood especially from the underside? I think I'll have to do this. Is it like adding and removing metal to door edges or is there other tricks?

Bill