SELLERSRODSHOP

Well-Known Member

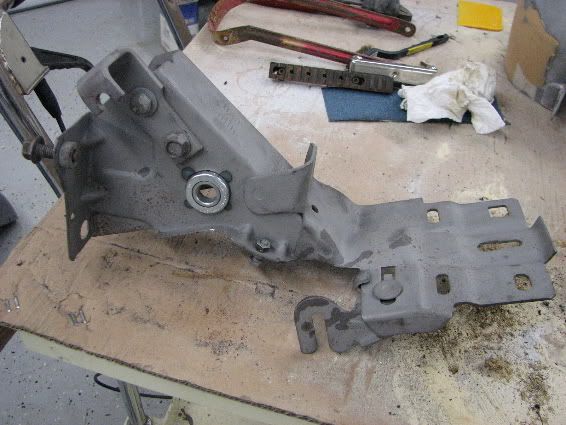

i'm in the process of rebuilding the pedal assembly that burned in the fire & decided to convert to bearings for the clutch pedal instead of the stock setup which consists of the potmetal bushings with plastic sleeves. i found a pair of radial bearings at tractor supply for $3 ea. that have 5/8" inside diameter holes that fit the pedal shaft.

http://wedo.hillmangroup.com/item/produ ... gs/58114-e?

i cut the original potmetal bushings out & opened up the holes to fit the bearings, checked alignment with the pedal & tacked them in place. they are 1/4" narrower than the stock bushings, so a small spacer will be in order on the outside & i will also add a sleeve between the bearings on the inside. if everything works well, it should be a cheaper alternative to the kits on the market now which i think run about $40.

http://wedo.hillmangroup.com/item/produ ... gs/58114-e?

i cut the original potmetal bushings out & opened up the holes to fit the bearings, checked alignment with the pedal & tacked them in place. they are 1/4" narrower than the stock bushings, so a small spacer will be in order on the outside & i will also add a sleeve between the bearings on the inside. if everything works well, it should be a cheaper alternative to the kits on the market now which i think run about $40.