sosADAMsos

New Member

I've been putting off this post for a long time (years...). Partly out of sheer laziness, but also partially out of embarrassment.

History: I was a young kid, with a great '66 coupe that I loved...

http://s984.photobucket.com/albums/ae328/sosADAMsos/1966%20Mustang%20Coupe/

but I needed more... plus, I was single and had all the time in the world to start a new project. So I did. Sure enough, I started dating my current girlfriend only one month later. Soon after I moved with her to San Francisco for 4 years (where I partied with Craig). Nearly 5 years since, I've been back in Orange County for almost two years and am still making progress (slowly).

I bought my 1965 Fastback from Stevea, a member of the VMF: http://forums.vintage-mustang.com/membe ... html :char

It was sold to me as nearly finished. "It comes with everything besides an engine"... "Just drop in a motor and your good to go". I was so young and desperate to get my hands on a fastback, I bought it... sight unseen.

Yeah, it was dumb. No, I would never do it again. But I was 18 at the time... In retrospect, I wouldn't have been able to see everything wrong with it even if I had seen it in person. This car was well covered up. Bondo'd and painted. If it had an engine, it surely wouldv'e had sawdust in it.

Anyways, here she is:

It's been nothing but problems since.

First, both the driver and passenger floors were replaced, but not in a way that would ever be safe to drive. It was tacked in, and covered with seam sealer. Not even welded to the frame rails. I wish I was kidding.

At the time I bought it, I not only couldn't weld, but did not own a welder. Well, I knew that was about to change... So I jumped in on the floors. I started by cutting threw the overlap, so that I could butt weld the two together, for a better finish.

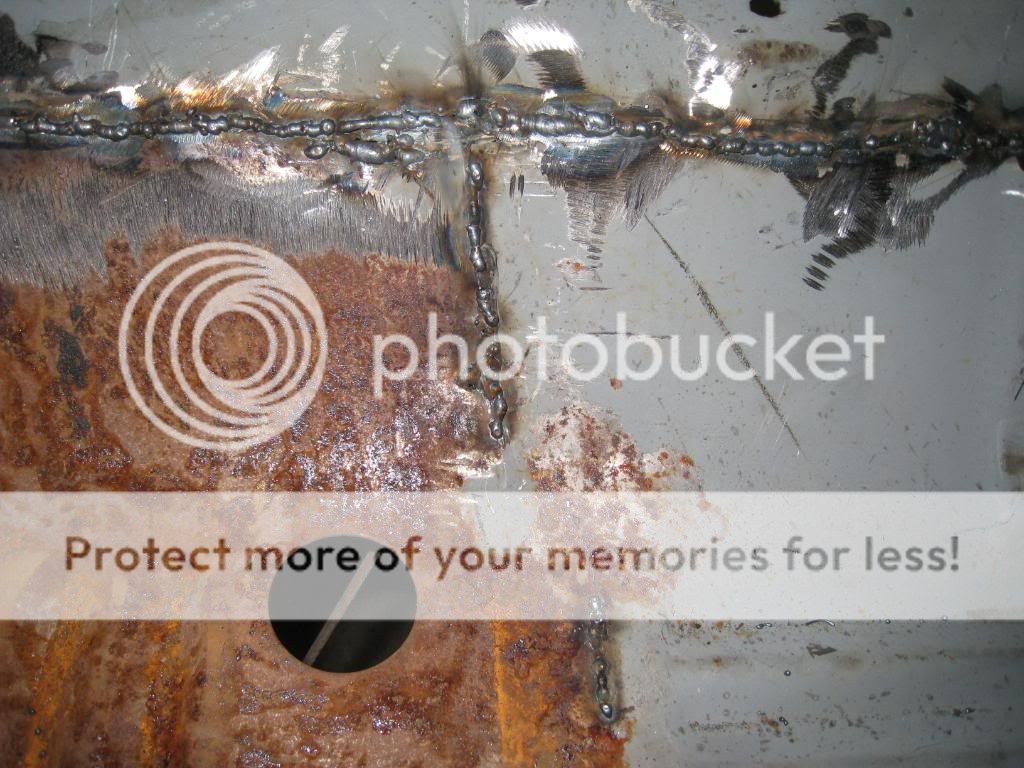

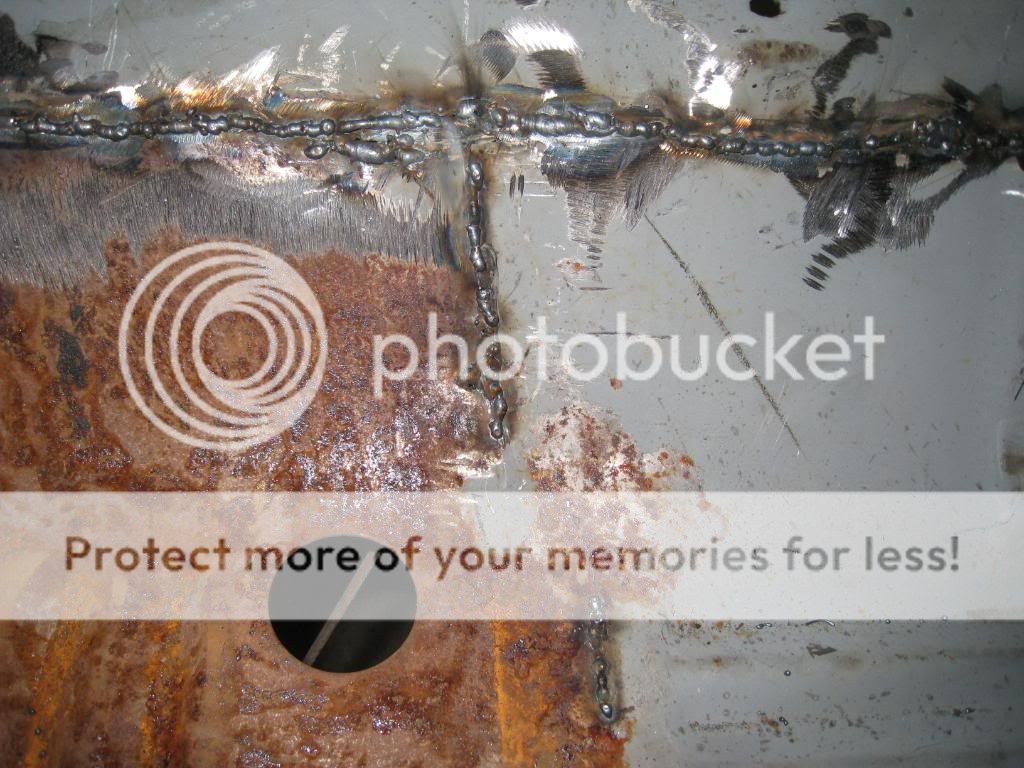

Some of my first welds. Ugly, I know. BUT, eventually I got the hang of it (as you'll see later in this monster post).

Ground down. Eventually covered with seam sealer and painted. I don't have photos of the finished floors, but I'll update soon with them.

Then we have the rusted through rear torque box, covered over with bondo (photos taken after wirebrushing all bondo away).

This was my first major panel replacement. Done in an unconventional way, I'm sure... but it worked:

Additional rusted panel in the rear floor, which was also replaced:

Moving on, we have the bondo'd holes in the firewall.

http://s984.photobucket.com/albums/ae32 ... G_0030.jpg

More rust where the pender apron meets the firewall (bondo'd of course...)

From inside:

Replacements:

The drivers side front frame rail was rusted out. The packed it with newspaper and covered it with bondo. Yes, THEY PACKED THE FRAME RAIL WITH NEWSPAPER AND COVERED IT WITH BONDO.

Outside, patched up. I decided to weld in the interior bumper bolts:

Inside, patched up:

Now, what I'm currently working on... replacing the driver's side rear inner wheel well, with the outer wheel well and fender install (A challenge... I know.)

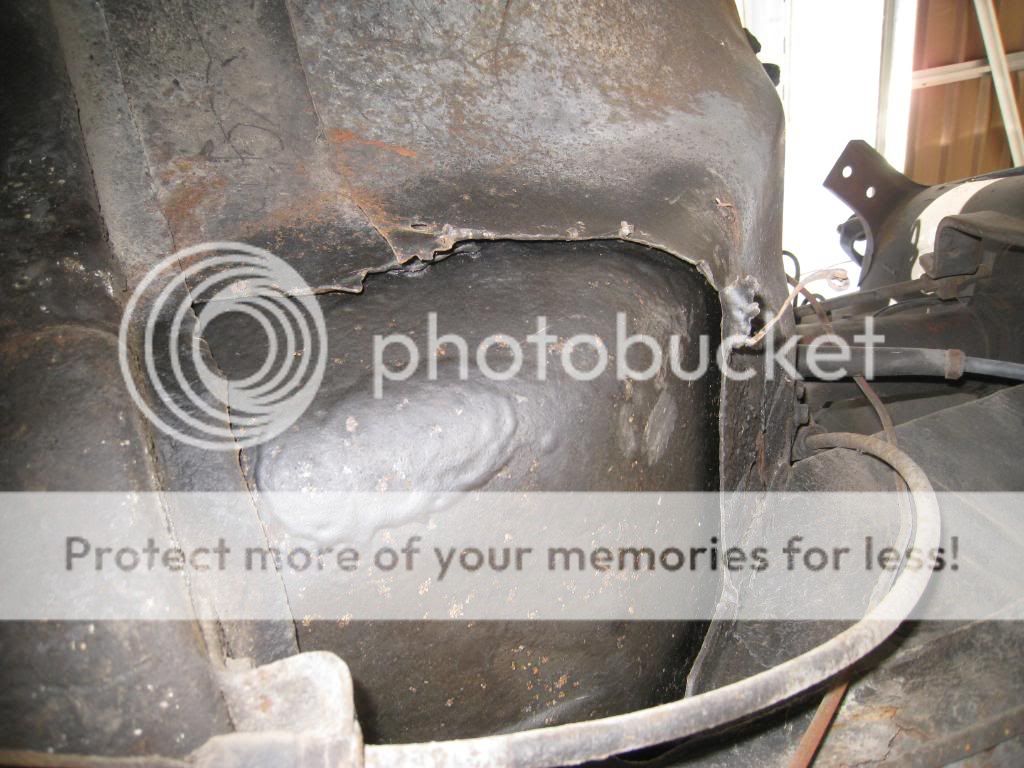

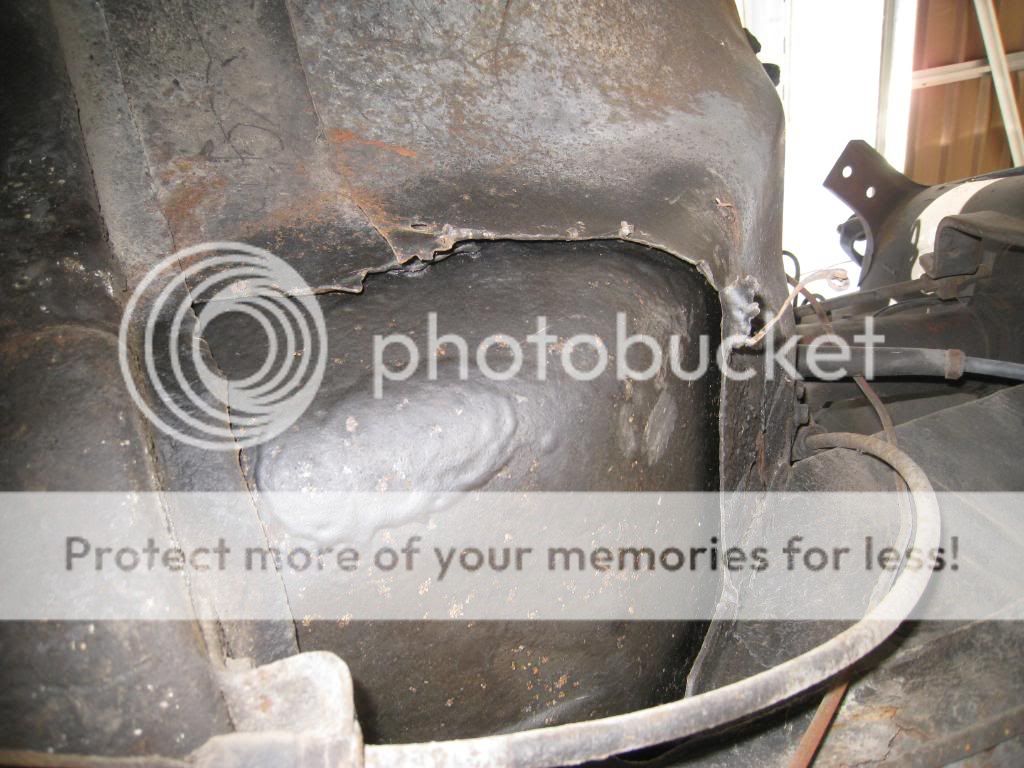

It was previously replaced...incorrectly. And there was a large gap between the outer and inner wheel well, which was bondo'd over:

Test fitment of the new interior wheel well showed I still had a large gap, and the outer well had to be pushed forward:

So, I pushed it forward

A much better fit:

And I still have a TON to do. Every time I fix something, I realize that 3 more things need to be fixed. As an example, nearly every weld is wrong on this car. Every panel is tacked, instead of plugged (and some of the welds are just plain UGLY):

So that, more or less, is where I'm at. I just keep my focus on someday being able to shift those gears, hear that roar, and be pushed back into my seat again. And on the bright side, I can weld now :roul

History: I was a young kid, with a great '66 coupe that I loved...

http://s984.photobucket.com/albums/ae328/sosADAMsos/1966%20Mustang%20Coupe/

but I needed more... plus, I was single and had all the time in the world to start a new project. So I did. Sure enough, I started dating my current girlfriend only one month later. Soon after I moved with her to San Francisco for 4 years (where I partied with Craig). Nearly 5 years since, I've been back in Orange County for almost two years and am still making progress (slowly).

I bought my 1965 Fastback from Stevea, a member of the VMF: http://forums.vintage-mustang.com/membe ... html :char

It was sold to me as nearly finished. "It comes with everything besides an engine"... "Just drop in a motor and your good to go". I was so young and desperate to get my hands on a fastback, I bought it... sight unseen.

Yeah, it was dumb. No, I would never do it again. But I was 18 at the time... In retrospect, I wouldn't have been able to see everything wrong with it even if I had seen it in person. This car was well covered up. Bondo'd and painted. If it had an engine, it surely wouldv'e had sawdust in it.

Anyways, here she is:

It's been nothing but problems since.

First, both the driver and passenger floors were replaced, but not in a way that would ever be safe to drive. It was tacked in, and covered with seam sealer. Not even welded to the frame rails. I wish I was kidding.

At the time I bought it, I not only couldn't weld, but did not own a welder. Well, I knew that was about to change... So I jumped in on the floors. I started by cutting threw the overlap, so that I could butt weld the two together, for a better finish.

Some of my first welds. Ugly, I know. BUT, eventually I got the hang of it (as you'll see later in this monster post).

Ground down. Eventually covered with seam sealer and painted. I don't have photos of the finished floors, but I'll update soon with them.

Then we have the rusted through rear torque box, covered over with bondo (photos taken after wirebrushing all bondo away).

This was my first major panel replacement. Done in an unconventional way, I'm sure... but it worked:

Additional rusted panel in the rear floor, which was also replaced:

Moving on, we have the bondo'd holes in the firewall.

http://s984.photobucket.com/albums/ae32 ... G_0030.jpg

More rust where the pender apron meets the firewall (bondo'd of course...)

From inside:

Replacements:

The drivers side front frame rail was rusted out. The packed it with newspaper and covered it with bondo. Yes, THEY PACKED THE FRAME RAIL WITH NEWSPAPER AND COVERED IT WITH BONDO.

Outside, patched up. I decided to weld in the interior bumper bolts:

Inside, patched up:

Now, what I'm currently working on... replacing the driver's side rear inner wheel well, with the outer wheel well and fender install (A challenge... I know.)

It was previously replaced...incorrectly. And there was a large gap between the outer and inner wheel well, which was bondo'd over:

Test fitment of the new interior wheel well showed I still had a large gap, and the outer well had to be pushed forward:

So, I pushed it forward

A much better fit:

And I still have a TON to do. Every time I fix something, I realize that 3 more things need to be fixed. As an example, nearly every weld is wrong on this car. Every panel is tacked, instead of plugged (and some of the welds are just plain UGLY):

So that, more or less, is where I'm at. I just keep my focus on someday being able to shift those gears, hear that roar, and be pushed back into my seat again. And on the bright side, I can weld now :roul

Last edited by a moderator: