I brought my car home in may of 2008. Prior to me owning it, it had been stored in a garage for 13 years uninspected, and not running. After a solid tune - up and fluid change, new battery, solenoid, and coil, I rebuilt the carb :lol, replaced the distributor, and it fired up. The motor was original, and just over 100k but would burn oil pretty bad.

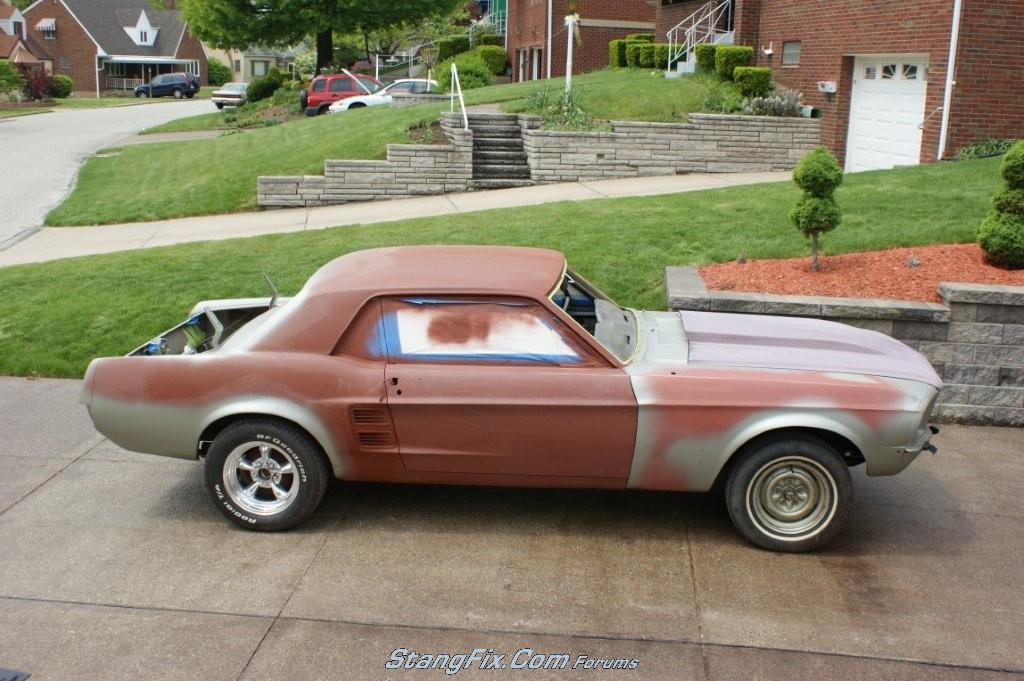

The day i brought it home:

Its amazing what a new set of wheels and a buff will do for a ride!

I knew of a 66 mustang coupe laying in a field, so i went to talk to the owner and was able to get a 289 from it. The transmission was already gone, the carb, water pump and accessories were already removed, but the motor would spin freely if turned by the harmonic balancer. So i brought it home.

The Owner of the motor had no idea if there had ever been any work done to it, but wouldnt let me lift the head to see. I had to wait till i got home to discover that it still had the standard 4.0 inch bore.

I drove the car all summer, It was an oil burning beast. But i made it to a bunch of car shows, and cruises, and even got a few dash plaques. I dont think any shows around here really do the trophy thing. I rebuilt the motor through the summer, doing it all myself except the boring and honning. It was bored .30 over, i used keith black hyperutectic pistons.

next came paint:

vodoo roller rockers, all alluminum setup edelbrock cam, carb, lifters, heads, timming cover, water pump, fuel pump, you name it.

The day i brought it home:

Its amazing what a new set of wheels and a buff will do for a ride!

I knew of a 66 mustang coupe laying in a field, so i went to talk to the owner and was able to get a 289 from it. The transmission was already gone, the carb, water pump and accessories were already removed, but the motor would spin freely if turned by the harmonic balancer. So i brought it home.

The Owner of the motor had no idea if there had ever been any work done to it, but wouldnt let me lift the head to see. I had to wait till i got home to discover that it still had the standard 4.0 inch bore.

I drove the car all summer, It was an oil burning beast. But i made it to a bunch of car shows, and cruises, and even got a few dash plaques. I dont think any shows around here really do the trophy thing. I rebuilt the motor through the summer, doing it all myself except the boring and honning. It was bored .30 over, i used keith black hyperutectic pistons.

next came paint:

vodoo roller rockers, all alluminum setup edelbrock cam, carb, lifters, heads, timming cover, water pump, fuel pump, you name it.

Last edited by a moderator: