I'm looking for advice on picking out an Intake Manifold.

The engine: 302 Roller Block

Bored .40 over

E303 Cam

Holley 4 Barrel with Vacuum Secondary 600 CFM

2.5" Exhaust with headers

Ram Air

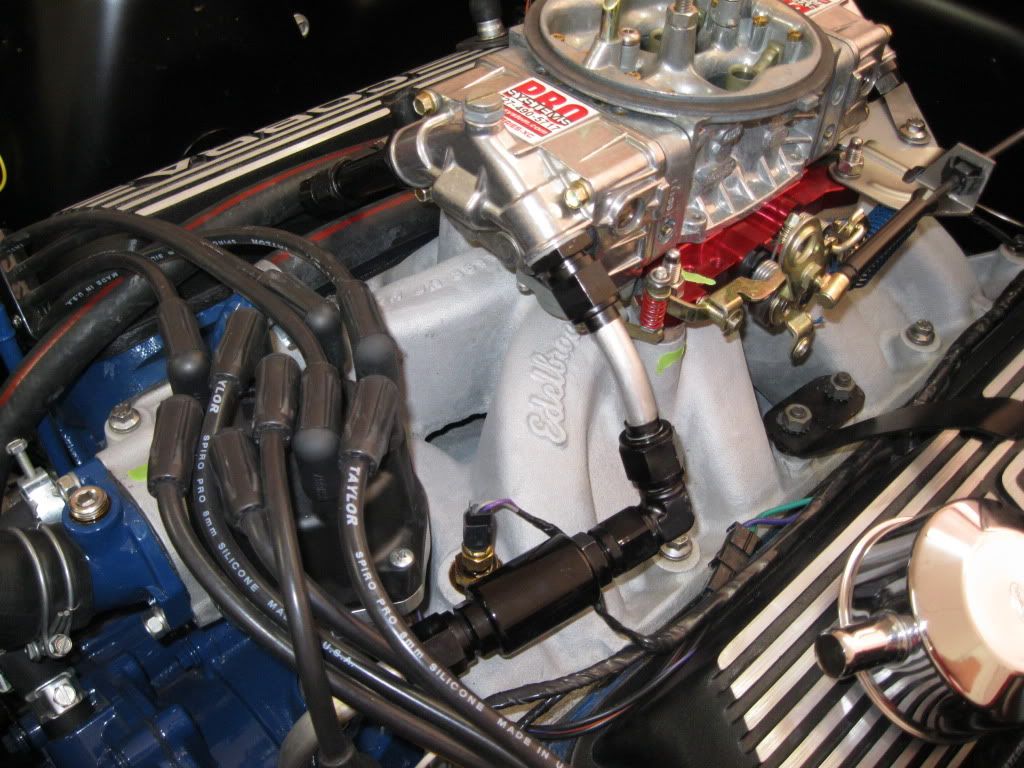

The engine had a Victor Jr. on it when I bought it, but one of the carb studs was stripped out so I put my old Performer on the engine. I'm really wondering if I should go back to the Victor Jr, and will it make that much difference? or do I go with another intake all together? or??????

The engine: 302 Roller Block

Bored .40 over

E303 Cam

Holley 4 Barrel with Vacuum Secondary 600 CFM

2.5" Exhaust with headers

Ram Air

The engine had a Victor Jr. on it when I bought it, but one of the carb studs was stripped out so I put my old Performer on the engine. I'm really wondering if I should go back to the Victor Jr, and will it make that much difference? or do I go with another intake all together? or??????