Hey all.

I am at the stage now where i want to add the brake plumbing on my car.

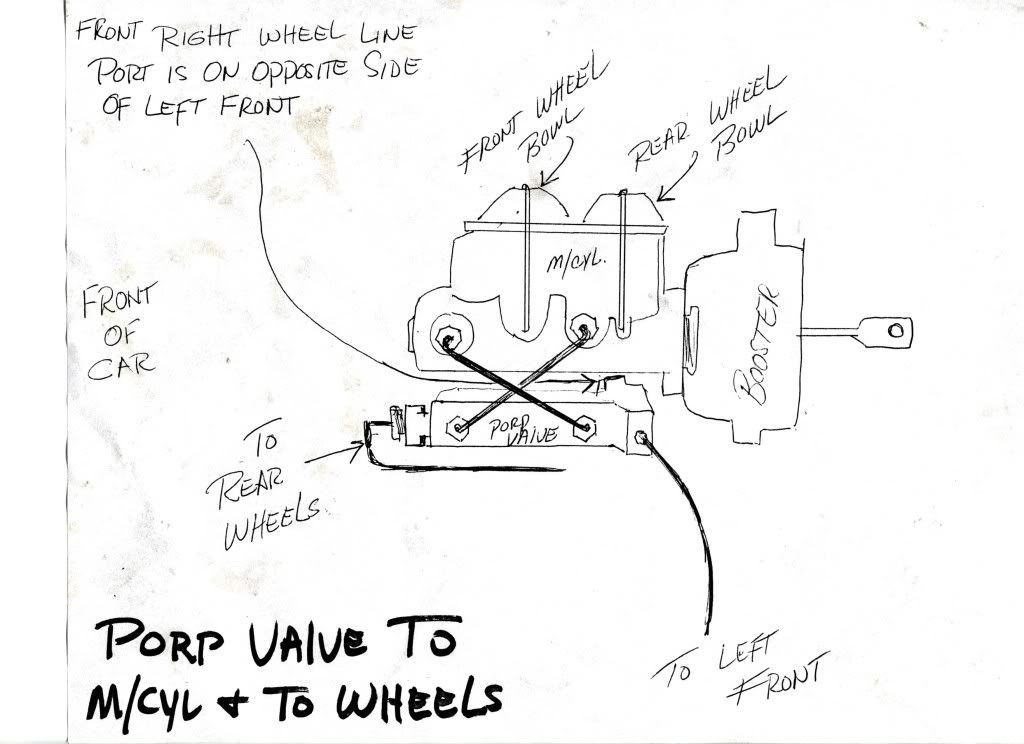

I am running Wilwood brakes front and back. (The rears have the internal parking brake). I have the Rod and Customs power booster/Master cylinder/prop valve unit and the flexible SS brake lines for the front to take me as far as the body.

http://www.rcmotorsports.net/17link.html

I could go down the avenue of bending and flaring all the lines from scratch which i dont mind doing however that depends if the pre bent lines need alot of work or whether they just slot right in.

I have found these two companies. Has anyone any experience with either of them?

http://www.classictube.com/index.asp

http://www.inlinetube.com/

For the parking park i was looking at using the Lokar setup. Again has anyone used this setup?

http://www.lokar.com/product-descriptions/univ-ebrake-cables.htm

I am trying to get together all parts that i will need to hook up brakes and parking brake so any tips on what i need to order will be greatly appreciated. Down to clips, brackets, fittings, etc etc

Thanks,

Johnny

I am at the stage now where i want to add the brake plumbing on my car.

I am running Wilwood brakes front and back. (The rears have the internal parking brake). I have the Rod and Customs power booster/Master cylinder/prop valve unit and the flexible SS brake lines for the front to take me as far as the body.

http://www.rcmotorsports.net/17link.html

I could go down the avenue of bending and flaring all the lines from scratch which i dont mind doing however that depends if the pre bent lines need alot of work or whether they just slot right in.

I have found these two companies. Has anyone any experience with either of them?

http://www.classictube.com/index.asp

http://www.inlinetube.com/

For the parking park i was looking at using the Lokar setup. Again has anyone used this setup?

http://www.lokar.com/product-descriptions/univ-ebrake-cables.htm

I am trying to get together all parts that i will need to hook up brakes and parking brake so any tips on what i need to order will be greatly appreciated. Down to clips, brackets, fittings, etc etc

Thanks,

Johnny