Jonk67

Well-Known Member

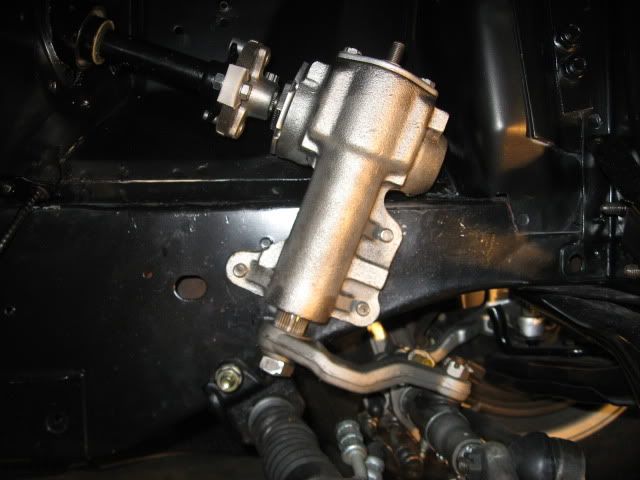

Ok, I've got my rebuilt steering gear box back from Stangerssite and I'm trying to install the pitman arm and it is locked up tighter than gorilla nuts and doesn't want to just ease onto the splines. It appears to be lined up with the splines, larger and smaller, I've sprayed it with WD, etc. to help slide but I only gotten ~1/2 turn out of the nut so far and it's so tight it stops and feels like I'm gonna bust something if I keep torqueing? Any tips? I'm using a large flat washer w/WD between the nut and pitman arm so the nut will spin w/o digging into the casing.

The control vavle end is already installed, could this be making it more difficult (cocking, ?) seems straight on the gear box shaft.

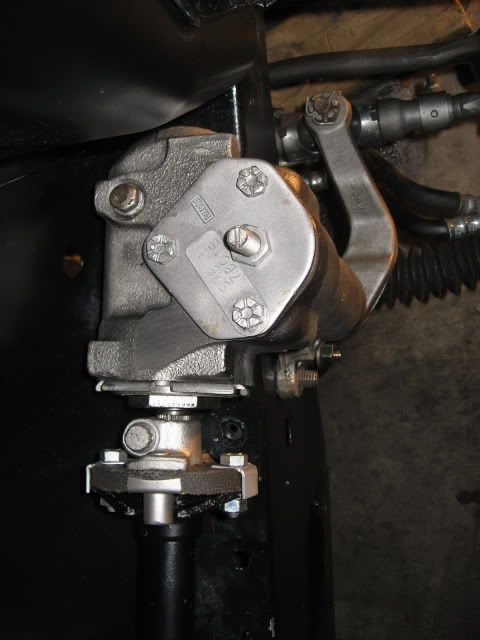

Also what size nut is it? I've got a 1 1/16" socket (too small) and a 1 1/8" (too big) what size is juuuust right?

Frustrated and want to get the suspension finished, column in, etc. so i can finally install the new engine.

Jon

The control vavle end is already installed, could this be making it more difficult (cocking, ?) seems straight on the gear box shaft.

Also what size nut is it? I've got a 1 1/16" socket (too small) and a 1 1/8" (too big) what size is juuuust right?

Frustrated and want to get the suspension finished, column in, etc. so i can finally install the new engine.

Jon