stump

Member

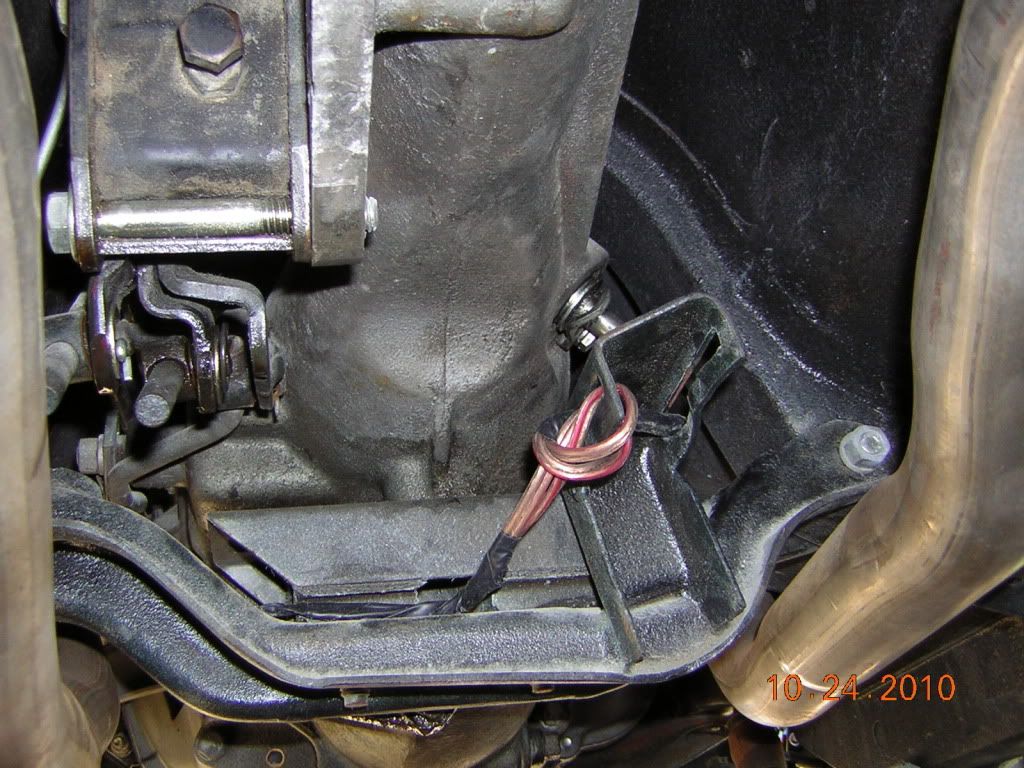

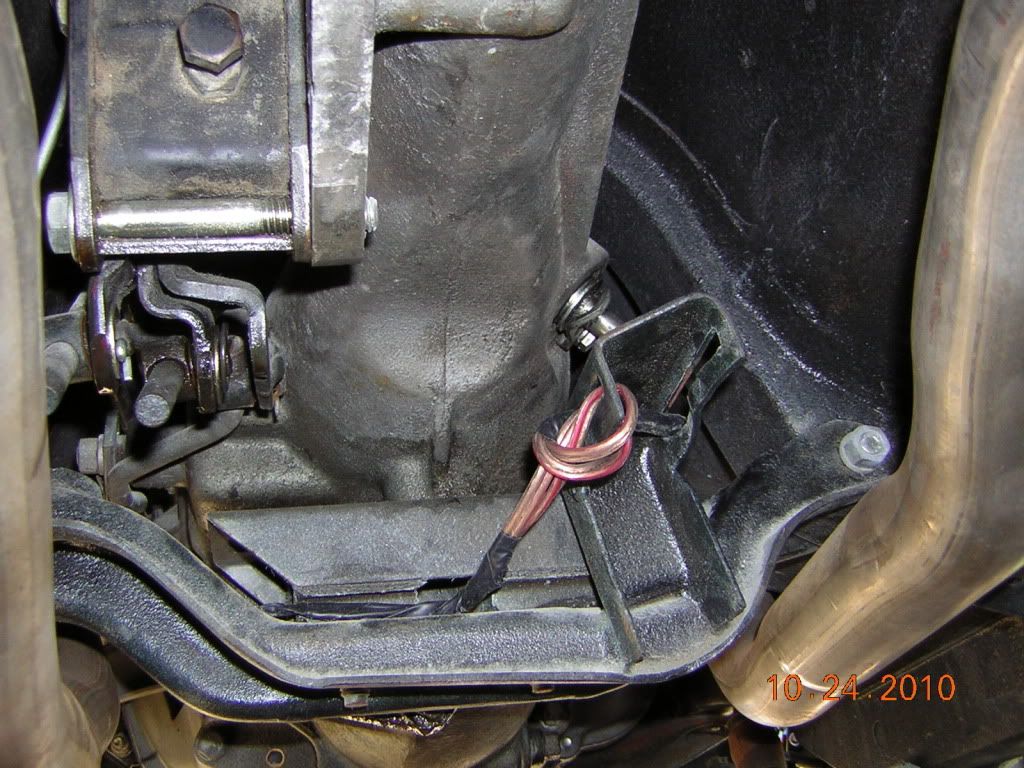

I'm hoping with the pictures attached someone can help me ID my transmission. Ultimately, I want to replace the shifter assembly, so is knowing it's a Hurst "Competition Plus" enough?

Thanks, Gary

Thanks, Gary

Last edited by a moderator: