Originally this car had a 260/4speed, it still has the 4 speed, but the SBF has been upgraded/updated to something blue, could be a 289 or a 302. It still has the 4 speed and I have a spare for it as well.

This car is an old family project, it was bought by my parents back in '84 and has been in storage of one sort or another since 1986. Since the last time it was registered in OR, it has approximately 2000 miles on the odometer. Those miles are from when we flat towed it using a tow bar from OR to ND in 1988; I don't know why Dad didn't pull the driveline, I was in my young teens at the time and didn't know any better. This car has been one of those projects that belongs to a family member that always intended to work on it, yet never found the time, then so much time passed that it because a white elephant and everybody was afraid to touch "Dad's Falcon". A few years ago, Dad gave it to me, last year I brought it home.

What is funny is that between this that I had not brought home a project in the 12 years that I've lived back in ND. Then last Spring, that suddenly changed.

It followed me home, and then I HAD to keep it..

And I also bought the boy a go-cart for his 5th birthday, I got to start them early...

The exterior of the car is in very decent shape with a few dents here and there, a mismatched passenger door, broke out driver side rear window, it is missing the truck lock mechanism.

I sold that brown 4dr thing in the background.

The front bumper doesn't look too bad.

The power top works great, the motor fired up and ran after who knows how long.

The clutch slips a little bit.

The brake system was completely dry of brake fluid.

The major exterior body damage is the driver front fender.

and the passenger quarter panel near the tail light.

I'd like to find a replacement fender, the quarter panel doesn't look like it should be too bad.

The real problem lies on the inside, under the rear seat.

The car was stored inside and on concrete most of the years, however that did not mean the roof didn't leak, nor did it mean that rain, snow, or mouse urine didn't get into the car.

I spent the better part of a day ripping off the rotten top material, tearing up the carpet, and removing detritus from interior and trunk.

As it was when I brought it home, full of random stuff, rust, and mouse droppings.

Emptied of its larger items, the rear seat looks good.

The front seats are trashed, but the floor pans are in great shape.

So now on to the bad parts...

The trunk drop offs are full of pin hole rust.

The other side isn't quite as bad.

Enough dancing.. the real problem is all related tot he rear seat support/divider.

The passenger side isn't any better.

And the biggest issue. That divider that holds up the front of the rear seat. Ford in all their brilliance did not provide any drains behind or through the vertical support. Any moisture that accumulated behind the divider ran forward and sat in that trough, eventually rusted through in its 30 years of storage.

Unfortunately, nobody makes replacement panels for a 1963 Falcon Convertible, so i will have to make my own.

Sadly other projects stacked up and I didn't make any progress on the Falcon over the winter until recently.

The Falcon was stored in the barn over winter, since there was no interior, I had no fear of mice or rodents.

Finally Spring had returned and out of storage the car came.

In April, I pulled it back into the shop and put it up on jackstands in preparation for a brake job.

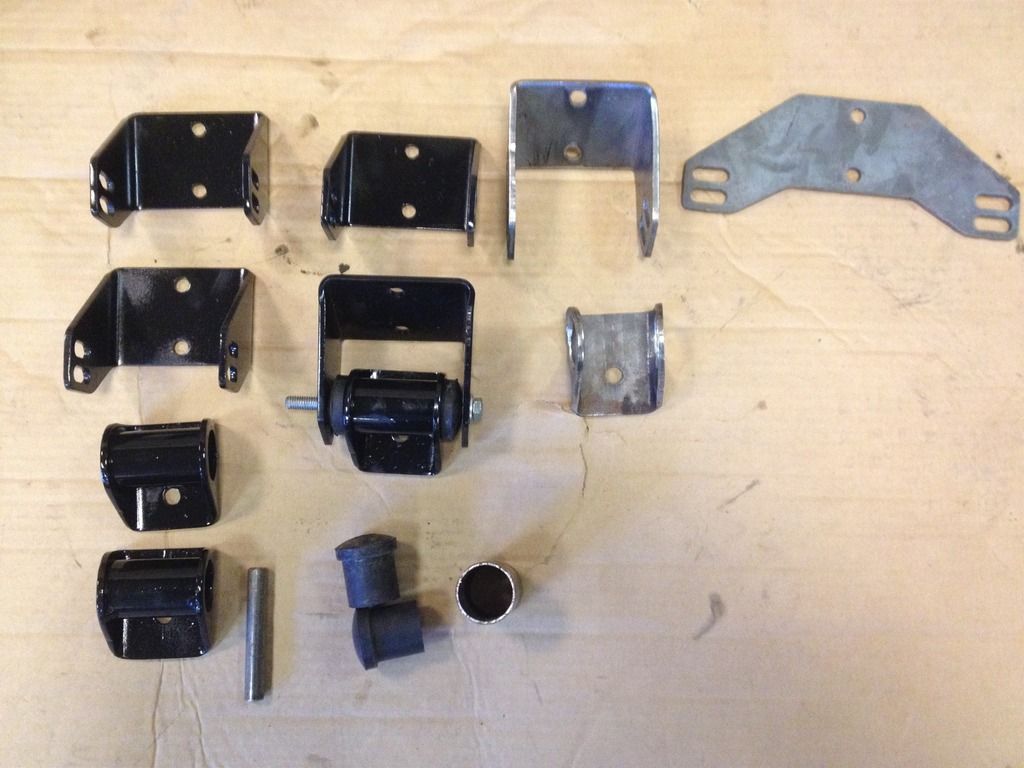

And that is where it sits today, I've installed a new master cylinder (original fruit jar style) and the rear wheel cylinders and brake hose have been replaced. I got stalled on the front wheel cylinders because the new ones have threaded bolt holes that are too small for my original wheel cylinder to backing plate bolts. Today I am off to get my core charge back from the MC and hopefully find some wheel cylinders with the right size bolt holes.

It may not be a Mustang, but it is the Mustang's Father...

This car is an old family project, it was bought by my parents back in '84 and has been in storage of one sort or another since 1986. Since the last time it was registered in OR, it has approximately 2000 miles on the odometer. Those miles are from when we flat towed it using a tow bar from OR to ND in 1988; I don't know why Dad didn't pull the driveline, I was in my young teens at the time and didn't know any better. This car has been one of those projects that belongs to a family member that always intended to work on it, yet never found the time, then so much time passed that it because a white elephant and everybody was afraid to touch "Dad's Falcon". A few years ago, Dad gave it to me, last year I brought it home.

What is funny is that between this that I had not brought home a project in the 12 years that I've lived back in ND. Then last Spring, that suddenly changed.

It followed me home, and then I HAD to keep it..

And I also bought the boy a go-cart for his 5th birthday, I got to start them early...

The exterior of the car is in very decent shape with a few dents here and there, a mismatched passenger door, broke out driver side rear window, it is missing the truck lock mechanism.

I sold that brown 4dr thing in the background.

The front bumper doesn't look too bad.

The power top works great, the motor fired up and ran after who knows how long.

The clutch slips a little bit.

The brake system was completely dry of brake fluid.

The major exterior body damage is the driver front fender.

and the passenger quarter panel near the tail light.

I'd like to find a replacement fender, the quarter panel doesn't look like it should be too bad.

The real problem lies on the inside, under the rear seat.

The car was stored inside and on concrete most of the years, however that did not mean the roof didn't leak, nor did it mean that rain, snow, or mouse urine didn't get into the car.

I spent the better part of a day ripping off the rotten top material, tearing up the carpet, and removing detritus from interior and trunk.

As it was when I brought it home, full of random stuff, rust, and mouse droppings.

Emptied of its larger items, the rear seat looks good.

The front seats are trashed, but the floor pans are in great shape.

So now on to the bad parts...

The trunk drop offs are full of pin hole rust.

The other side isn't quite as bad.

Enough dancing.. the real problem is all related tot he rear seat support/divider.

The passenger side isn't any better.

And the biggest issue. That divider that holds up the front of the rear seat. Ford in all their brilliance did not provide any drains behind or through the vertical support. Any moisture that accumulated behind the divider ran forward and sat in that trough, eventually rusted through in its 30 years of storage.

Unfortunately, nobody makes replacement panels for a 1963 Falcon Convertible, so i will have to make my own.

Sadly other projects stacked up and I didn't make any progress on the Falcon over the winter until recently.

The Falcon was stored in the barn over winter, since there was no interior, I had no fear of mice or rodents.

Finally Spring had returned and out of storage the car came.

In April, I pulled it back into the shop and put it up on jackstands in preparation for a brake job.

And that is where it sits today, I've installed a new master cylinder (original fruit jar style) and the rear wheel cylinders and brake hose have been replaced. I got stalled on the front wheel cylinders because the new ones have threaded bolt holes that are too small for my original wheel cylinder to backing plate bolts. Today I am off to get my core charge back from the MC and hopefully find some wheel cylinders with the right size bolt holes.

It may not be a Mustang, but it is the Mustang's Father...