I suggest you measure up the center lines on the four end holes and determine just what ends you are dealing with. It doesn't look like any standard Ford end I have seen. Also use a depth gauge or caliper to see how deep the bearing recess is and also the bearing. It should mount flush or deeper. Is there no inner ridge against which the seal sits? If there is how deep is it?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

-

Hello there guest and Welcome to The #1 Classic Mustang forum!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

axles wont go in

- Thread starter blown66

- Start date

dodgestang

Active Member

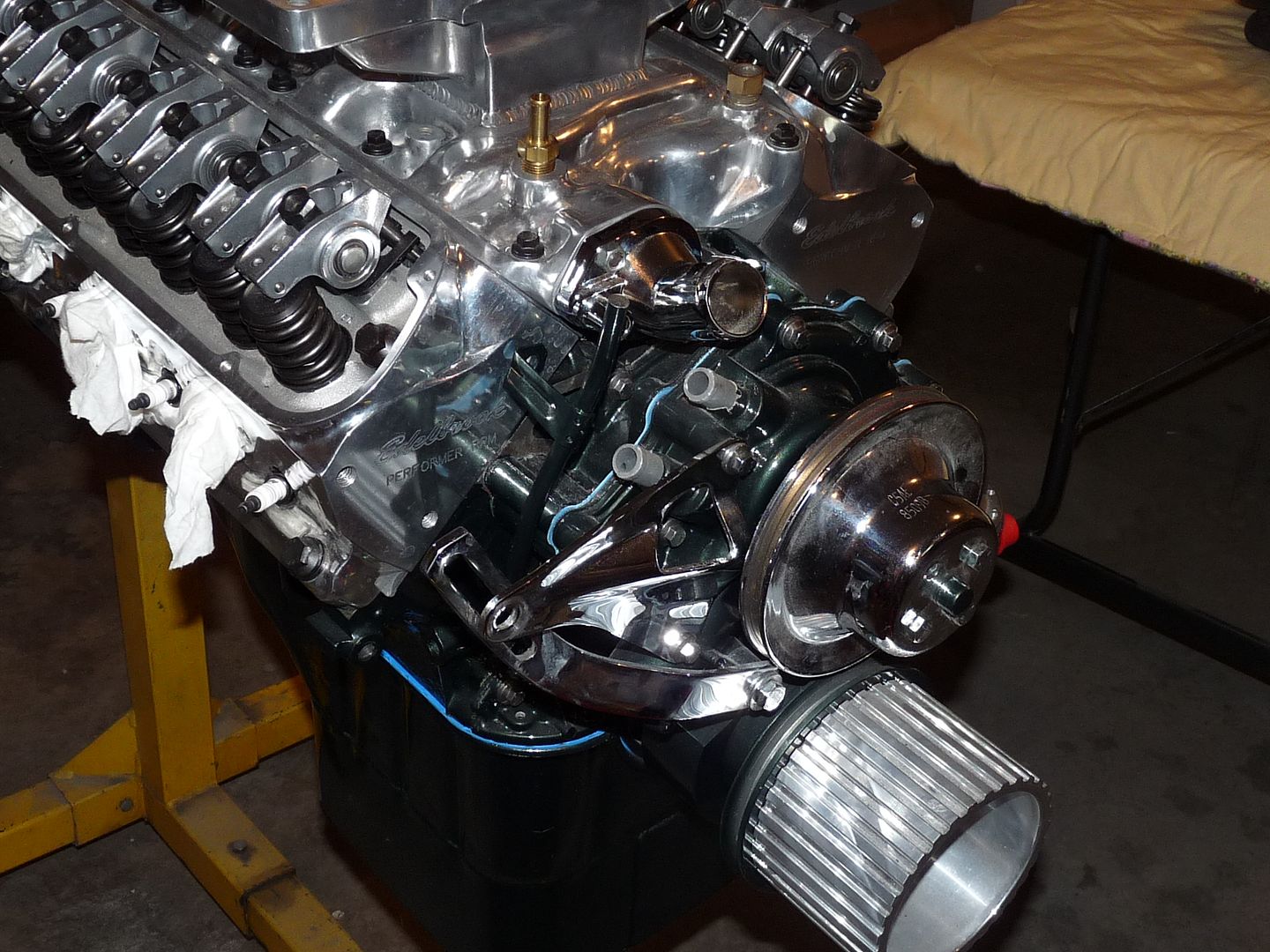

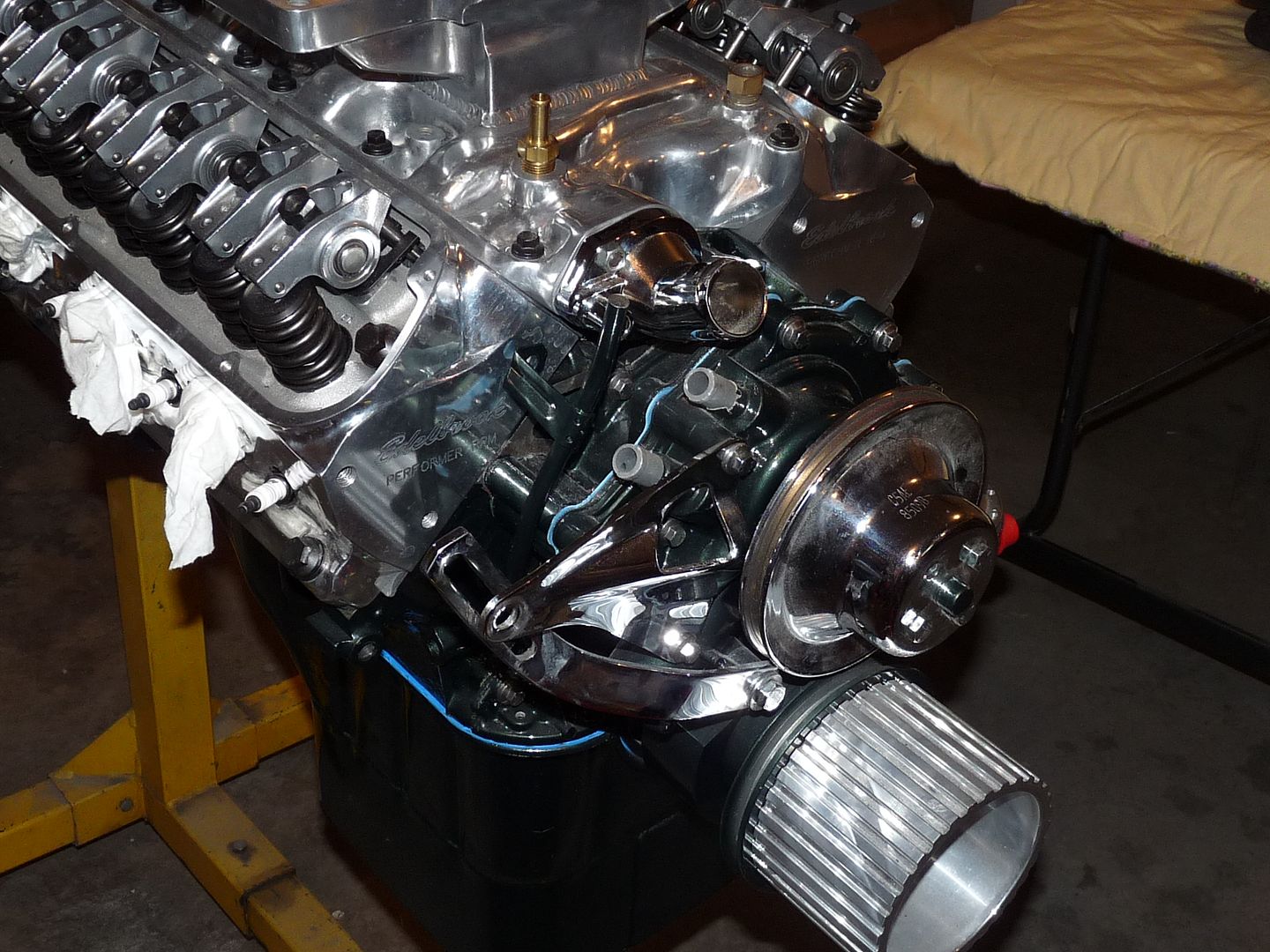

This is how the bearings fit in my 9 inch rear end in my 65 and in my 67. I run the later style bearing with the o ring that seals built into it.

Wow.....that certainly isn't working

Aside from the mention possibilities of:

1. Spline mismatch between your rebuilt carrier and the axles

2. In tube oil seals not installed correctly

3. NEW - are you sure it is the right bearing? It could be slightly oversized and incorrect do you have the old ones to measure with a micrometer (or did you and record the size previously)?

Dyno68FB

Member

Blown66: I went through something similar early in my build. Below is the thread. Also Dutchman Motorsports was a huge help. I think the guy who helped me was drew. He knew more about 9in rear ends then anyone I have ever spoke with. And they are great to deal with. My issue came down to the wrong seals. Might be worth a read.

http://www.stangfix.com/index.php?posts/257665/

http://www.stangfix.com/index.php?posts/257665/

blown66

Member

3. NEW - are you sure it is the right bearing? It could be slightly oversized and incorrect do you have the old ones to measure with a micrometer (or did you and record the size previously)?

I never changed the axle bearings and collar just the axle oil seal in the housing.

blown66

Member

1. Spline mismatch between your rebuilt carrier and the axles

Nothing was changed in the carrier just cleaned up and new bearing and all. It turned fine before I put it in and it turns when I turn it installed.

blown66

Member

I suggest you measure up the center lines on the four end holes and determine just what ends you are dealing with. It doesn't look like any standard Ford end I have seen. Also use a depth gauge or caliper to see how deep the bearing recess is and also the bearing. It should mount flush or deeper. Is there no inner ridge against which the seal sits? If there is how deep is it?

I am talking about the oil seal in the housing. The axle bearing are fine. there is a ridge where the axle bearing sits and it looks like there is one on the housing also for the oil seal. I have been doing some searching on the net and I have searched the old bearing number and have found out that the bearings that where in there are from years NORS 1957-1967 Ford pass Edsel Mercury rear seals B7A1177B AJ1177D.....there is a picture of them and they are the right ones number matching. I will be calling auto parts tomorrow and see if they have or can get these seals. The Number on the original seals are..Part Brand C/R Manufacturer part number 13765....

blown66

Member

did some searching and found this. These are the same oil seals that I took out. same part number and all. I will see if the parts stores can help me tomorrow. will let you know. thank you all very much for the replys.

http://www.ebay.com/itm/141109897254?ssPageName=STRK:MEBIDX:IT&fromMakeTrack=true

http://www.ebay.com/itm/141109897254?ssPageName=STRK:MEBIDX:IT&fromMakeTrack=true

Grabber70Mach

Well-Known Member

I ran into an issue when I replaced my axle seals. Found out I had been given the incorrect ones. I needed seals for a W axle or something along those lines.

From infinity and beyond

From infinity and beyond

blown66

Member

I ran into an issue when I replaced my axle seals. Found out I had been given the incorrect ones. I needed seals for a W axle or something along those lines.

From infinity and beyond

Thanks for the info...I will be going to the parts store soon and see what they can do. Will post later what I find out.

blown66

Member

wow after about 2 hrs at the auto place this evening came down to there is a problem with the 3rd member they think. They wanted me to pull the 3rd member and bring it in tomorrow to show the owners that have been there for ever and would check it out to see what is going on. I have a couple videos to show you.

just started to pop the 3rd member up

third member out

first video

second video

I will post tomorrow what we find out..again thank you for you time and replys. God bless

just started to pop the 3rd member up

third member out

first video

second video

I will post tomorrow what we find out..again thank you for you time and replys. God bless

Did you slide the axles into the gears once you removed the chunk?

I think Mark means slide the axles into axle housing with the chunk removed. Will they now slide in?

The focus is horrible on those videos but it looks like there is an alignment issue. Might just be the camera angle. I will have to go look at some stuff because I'm not sure I understand how it could happen.

Ponyman66

Yak, yak, yak

After graduating high school I worked at a local Ford dealership as a mechanic, specializing in manual transmissions and differentials. I've pulled and reinstalled more than a couple of sets of axle shafts! I've been following your thread for a bit now and closely watching all of your comments as well as examining your pictures closely. I didn't want to post any suggestions too quickly until I had what I felt was a pretty complete picture of your situation. This is what I've been able to see; your replacement axle seal appears to have been seated correctly. If it fit over the seal surface on the axle shaft, it was the correct one to begin with. Many modern seals will not look exactly as the original stuff. What matters is outer diameter, inner (sealing surface) diameter, depth and seal type (e.g. double lip or single lip seals). The appearance of the carrier splines seeming to be out of alignment is not possible. If an incorrect carrier bearing was installed it would not fit over the end of the carrier properly, nor would it sit into the bearing saddle properly. If the bearing is fitting both surfaces properly (which it appears to be), the splines of the carrier will be in proper alignment.

Based on everything I've read from your posts and pictures/video I'd have to come to one conclusion, you aren't getting the spline end of the axle into the carrier opening, plain and simple. Based on the pictures you posted with the axle going in without the seal, but not with the seal installed shows it is engaging properly. It's also seated at the proper depth in the " no seal installed" photo. Based on the lower photo and the comments you made about putting the bolts into the retainer plate causing the axle to lock down further tells me misalignment of the shaft at the carrier end. With the seal out you have the entire diameter of the axle housing tube in which to move the shaft around to align it for engagement. When you have the seal installed there isn't much room to compensate for error. What appears is happening is you're poking it into the area of the adjustment spanner nut or against the end of the ring gear carrier. When you installed the bolts to try to draw the shaft in you were just lock the tip of the axle against the spanner nut. Remember, when you have the shaft most of the way in and start moving the flange to align it, a little movement on the axle flange translates into a large amount of movement at the spline end. Sometimes they can be a total bear to seat!

I'd suggest putting everything back together and ready to accept the axle shafts. Insert the axle shaft into the housing, supporting the center with one hand and the other hand on the flange. Once you have it in approximately 2/3's of the way, grab the axle flange with both hands, one hand opposite the other on the flange. Slide the shaft into the housing keeping the shaft as level and straight as you can, as far as you can. As soon as you feel contact with anything, gently push a little harder. Also, turn the shaft back and forth slightly to allow for spline alignment as you push. Keep in mind there is a smaller taper to the opening of the ring gear carrier at the axle shaft opening. This helps a little in alignment. If the edge of the shaft is against that taper, the additional pressure will force the shaft into the opening in proper alignment. You'll also see the axle shaft bearing going deeper into the axle housing. It may then take a few gentle taps with a hammer on the flange to seat it fully. If it DIDN'T hit the taper, you're still against the end of the ring gear carrier end. Wiggle it GENTLY and in SMALL movements. You should be able to feel it when it falls into alignment. At that point PUSH, you don't want it dropping back out!! Also keep in mind when you're moving it around holding just the axle flange, you don't have a whole lot of leverage. I usually make the up/down or side to side corrections with my finger tips while countering with pressure on the heels of my palms for leverage (I hope that's a clear explanation of that point!). As I said, some go in easily (luck!), and some are a total PITA! One final suggestion, once you start the axle into the housing while holding the axle flange, close your eyes. Just concentrate on what you're feeling and not what you're seeing. I'm not screwing with you, I'm totally serious. It truly works! Good luck with it and keep us all posted!

Based on everything I've read from your posts and pictures/video I'd have to come to one conclusion, you aren't getting the spline end of the axle into the carrier opening, plain and simple. Based on the pictures you posted with the axle going in without the seal, but not with the seal installed shows it is engaging properly. It's also seated at the proper depth in the " no seal installed" photo. Based on the lower photo and the comments you made about putting the bolts into the retainer plate causing the axle to lock down further tells me misalignment of the shaft at the carrier end. With the seal out you have the entire diameter of the axle housing tube in which to move the shaft around to align it for engagement. When you have the seal installed there isn't much room to compensate for error. What appears is happening is you're poking it into the area of the adjustment spanner nut or against the end of the ring gear carrier. When you installed the bolts to try to draw the shaft in you were just lock the tip of the axle against the spanner nut. Remember, when you have the shaft most of the way in and start moving the flange to align it, a little movement on the axle flange translates into a large amount of movement at the spline end. Sometimes they can be a total bear to seat!

I'd suggest putting everything back together and ready to accept the axle shafts. Insert the axle shaft into the housing, supporting the center with one hand and the other hand on the flange. Once you have it in approximately 2/3's of the way, grab the axle flange with both hands, one hand opposite the other on the flange. Slide the shaft into the housing keeping the shaft as level and straight as you can, as far as you can. As soon as you feel contact with anything, gently push a little harder. Also, turn the shaft back and forth slightly to allow for spline alignment as you push. Keep in mind there is a smaller taper to the opening of the ring gear carrier at the axle shaft opening. This helps a little in alignment. If the edge of the shaft is against that taper, the additional pressure will force the shaft into the opening in proper alignment. You'll also see the axle shaft bearing going deeper into the axle housing. It may then take a few gentle taps with a hammer on the flange to seat it fully. If it DIDN'T hit the taper, you're still against the end of the ring gear carrier end. Wiggle it GENTLY and in SMALL movements. You should be able to feel it when it falls into alignment. At that point PUSH, you don't want it dropping back out!! Also keep in mind when you're moving it around holding just the axle flange, you don't have a whole lot of leverage. I usually make the up/down or side to side corrections with my finger tips while countering with pressure on the heels of my palms for leverage (I hope that's a clear explanation of that point!). As I said, some go in easily (luck!), and some are a total PITA! One final suggestion, once you start the axle into the housing while holding the axle flange, close your eyes. Just concentrate on what you're feeling and not what you're seeing. I'm not screwing with you, I'm totally serious. It truly works! Good luck with it and keep us all posted!

blown66

Member

horseplay reply 14 was what was wrong. I never had the axle oil seal in far enough. DAUGH! I really do appreciate all the brain storming and your time. THANK YOU. I got the backing plates and the axles in about a hr ago and that felt good that they went right in. I will be posting some pictures today some time with the axles installed..woo hoo!!!!...any way I am a happy camper and will hopefully install the rear end back in the mustang today or sunday. hey when you guys are installing the 3rd member in the housing how did you keep it from trying to run away from you? Again thank you.

Grabber70Mach

Well-Known Member

That's great, Thanks for letting us know.

From Infinity and beyond

From Infinity and beyond

blown66

Member

blown66

Member

few pictures with brake lines on

http://www.seahawks.com/videos-phot...-Preview/a4854495-a9c9-448e-a5b5-49890ec1c5f7

http://www.seahawks.com/videos-phot...-Preview/a4854495-a9c9-448e-a5b5-49890ec1c5f7