Jonk67

Well-Known Member

Ok, I've got my red 1/0 cable and have started laying out my route from trunk to starter. I plan to place the battery where the black box is, right on top of the rear end to the right side. I have an altima redtop that I will lay down posts towards the trunk and leave extra cable so I can pull it to where the spare tire is if I need to get to it which I don't expect to often. The right side of the box will be bolted through to the frame and I'll probably add some 1/4" flat bar to tie the right side of the box to the frame too. I will be using rubber grommets where ever I go through a hole.

How does this route through the rear look? Where it is laying it clears the rear seat panel and window operation. I cut/bent/folded the thin piece of metal at the floor to keep from cutting the cable and will put some slit fuel hose over top/bottom metal edges to protect it. Does this look ok for a route? From here it runs forward down the rocker channel to the front kick panel.

In the front I am inside the kick panel and trying to find the shortest/easiest/least prone to water outlet. I tried it through the antenna hole but that's doesn't seem very direct. I'm thinking of drilling a hole where the blue tape is in the firewall if I can get the cable past the heater motor up in that corner. Of course I refurbed the heater and reinstalled before doing the cable...

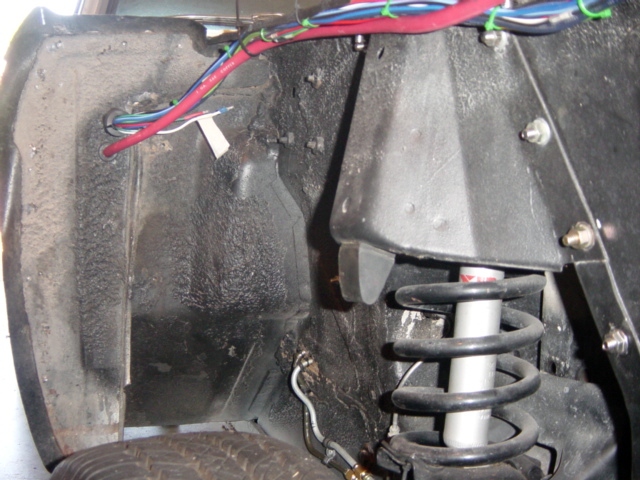

I am probably going to enter the engine bay where the blue tape is forward of the shock tower as I'll also be putting a junction box there for all my forward electrics (headlight relays, etc.). I was going to go through where there's already a hole pointing right at the starter but my headers allow no room to go through. I figured it'll be easier to come from the front of the headers and between them and the block to the starter.

Tips, hints, ideas?

Jon

How does this route through the rear look? Where it is laying it clears the rear seat panel and window operation. I cut/bent/folded the thin piece of metal at the floor to keep from cutting the cable and will put some slit fuel hose over top/bottom metal edges to protect it. Does this look ok for a route? From here it runs forward down the rocker channel to the front kick panel.

In the front I am inside the kick panel and trying to find the shortest/easiest/least prone to water outlet. I tried it through the antenna hole but that's doesn't seem very direct. I'm thinking of drilling a hole where the blue tape is in the firewall if I can get the cable past the heater motor up in that corner. Of course I refurbed the heater and reinstalled before doing the cable...

I am probably going to enter the engine bay where the blue tape is forward of the shock tower as I'll also be putting a junction box there for all my forward electrics (headlight relays, etc.). I was going to go through where there's already a hole pointing right at the starter but my headers allow no room to go through. I figured it'll be easier to come from the front of the headers and between them and the block to the starter.

Tips, hints, ideas?

Jon