LastDeadLast

Member

Hello folks,

I'm starting a build thread here. Most of my work so far is electrical. I bought a 5.0 engine from a 90 Mustang GT and a harness from RJM to run it all. Since a lot of the electrical was ripped out by the PO, I got a replacement harness from Painless Wiring. The harness was nice I guess, but a lot of money for what I got. If I had to do it over again, I'd go with a basic kit. This is especially true since I upgraded the headlight wiring in order to handle higher wattage lights... PLUS much of the factory engine wiring is replaced by the EFI harness. All in all, quite a few wires of the Painless harness had to be taken out because I wasn't going to use them.

Since the car came with strips and kinda looks like a race car, I'm going for a road-racer look... and I'm setting up the suspension and brakes accordingly. The car came with the sub-frame connectors and a 6pt roll cage installed, so it's pretty darned stiff for a vert.

Anyway, here's what I envision:

Engine-Drivetrain:

1990 5.0 EFI

Electric fan

JBA shorty headers

T-5z gearbox

Aluminum driveshaft

9" diff 3.89 gears/Detroit TrueTrac/Moser Axles

13" Cobra front brakes, 11.65 Cobra rear brakes from Street or Track

Vintage Wheel Works 17"x8" V-48 wheels 4.75" offset

235/45-17 Direzza Sport Z1 Star Spec tires

Suspension/Brakes/Steering:

Global West rear leaf springs with Del-alum bushings

Global West sub-frame connectors

6-pt roll cage

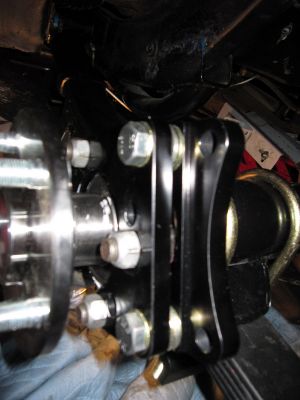

Street or Track front UCA/LCA/Strut bar

1" Sway bar

Bilstein shocks f/r

Borgeson power steering module

Strut tower brace

620 front springs

Electrical:

Battery/Solenoid re-located to the trunk

Painless main harness

RJM EFI harness

Upgraded wiring for headlights, driving lights and electric fan

Interior:

Fiero seats (eventually)

Air conditioning

Custom aluminum radio delete panel

As purchased:

Radio delete panel:

Trunk - battery rerouting:

I'll be really getting into the suspension install in a week or so, I'll post more pics as I take them.

-Shannon

I'm starting a build thread here. Most of my work so far is electrical. I bought a 5.0 engine from a 90 Mustang GT and a harness from RJM to run it all. Since a lot of the electrical was ripped out by the PO, I got a replacement harness from Painless Wiring. The harness was nice I guess, but a lot of money for what I got. If I had to do it over again, I'd go with a basic kit. This is especially true since I upgraded the headlight wiring in order to handle higher wattage lights... PLUS much of the factory engine wiring is replaced by the EFI harness. All in all, quite a few wires of the Painless harness had to be taken out because I wasn't going to use them.

Since the car came with strips and kinda looks like a race car, I'm going for a road-racer look... and I'm setting up the suspension and brakes accordingly. The car came with the sub-frame connectors and a 6pt roll cage installed, so it's pretty darned stiff for a vert.

Anyway, here's what I envision:

Engine-Drivetrain:

1990 5.0 EFI

Electric fan

JBA shorty headers

T-5z gearbox

Aluminum driveshaft

9" diff 3.89 gears/Detroit TrueTrac/Moser Axles

13" Cobra front brakes, 11.65 Cobra rear brakes from Street or Track

Vintage Wheel Works 17"x8" V-48 wheels 4.75" offset

235/45-17 Direzza Sport Z1 Star Spec tires

Suspension/Brakes/Steering:

Global West rear leaf springs with Del-alum bushings

Global West sub-frame connectors

6-pt roll cage

Street or Track front UCA/LCA/Strut bar

1" Sway bar

Bilstein shocks f/r

Borgeson power steering module

Strut tower brace

620 front springs

Electrical:

Battery/Solenoid re-located to the trunk

Painless main harness

RJM EFI harness

Upgraded wiring for headlights, driving lights and electric fan

Interior:

Fiero seats (eventually)

Air conditioning

Custom aluminum radio delete panel

As purchased:

Radio delete panel:

Trunk - battery rerouting:

I'll be really getting into the suspension install in a week or so, I'll post more pics as I take them.

-Shannon

Last edited by a moderator: