Jonk67

Well-Known Member

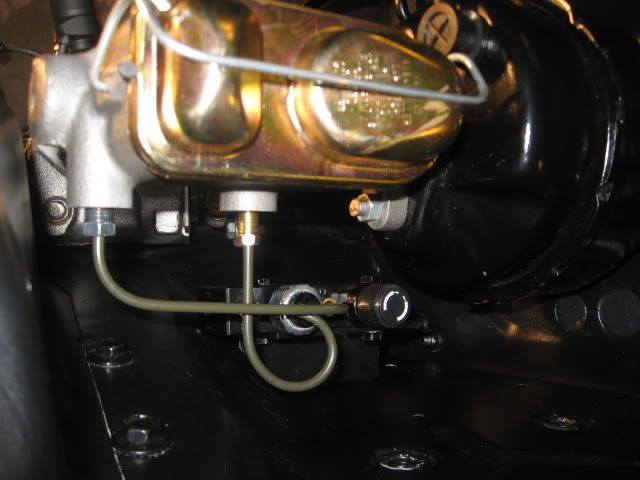

Mounted up my booster and MC, fabbed a bracket to hold the Summit (SSBC) distribution/prop valve and started running lines. Picked up the polymer lines from NAPA, pretty impressed with them, hard to scratch unless you use pliers on them...rented their bending/flaring kit which is really nice also, benders are like pliers. I think I'll be doing all my brake lines with this polymer stuff.

Give me some pointers on my lines, I picked up prefabbed 8" lines with mixed fittings to fit the forward inlet (rear brakes), do I really have to have a loop in it for that much flex? Should it move enough to need more than the slant it could flex a little? I'm hoping I'm good to go otherwise I'll have to get a 12" one and cut/flare/loop which is ok but I'd rather do it right NOW.

I can get the brake light switch wiring pigtail on as it is right now too.

Thanks, Jon

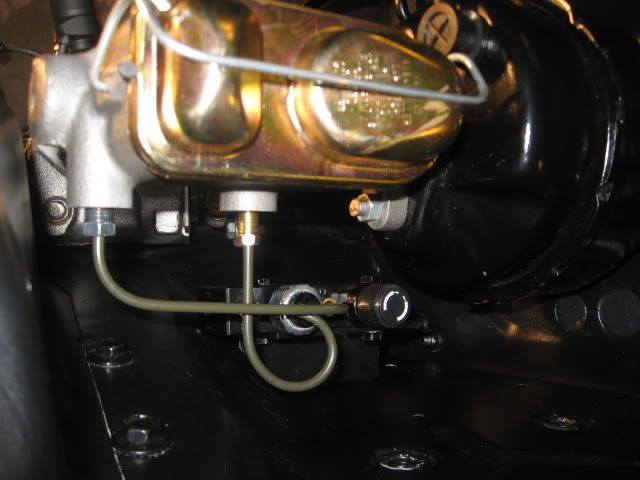

Give me some pointers on my lines, I picked up prefabbed 8" lines with mixed fittings to fit the forward inlet (rear brakes), do I really have to have a loop in it for that much flex? Should it move enough to need more than the slant it could flex a little? I'm hoping I'm good to go otherwise I'll have to get a 12" one and cut/flare/loop which is ok but I'd rather do it right NOW.

I can get the brake light switch wiring pigtail on as it is right now too.

Thanks, Jon