MD69Boss

Suspected Troll

Replaced the voltage regulator, what should have been a 20 min job ended up taking about 90 min...

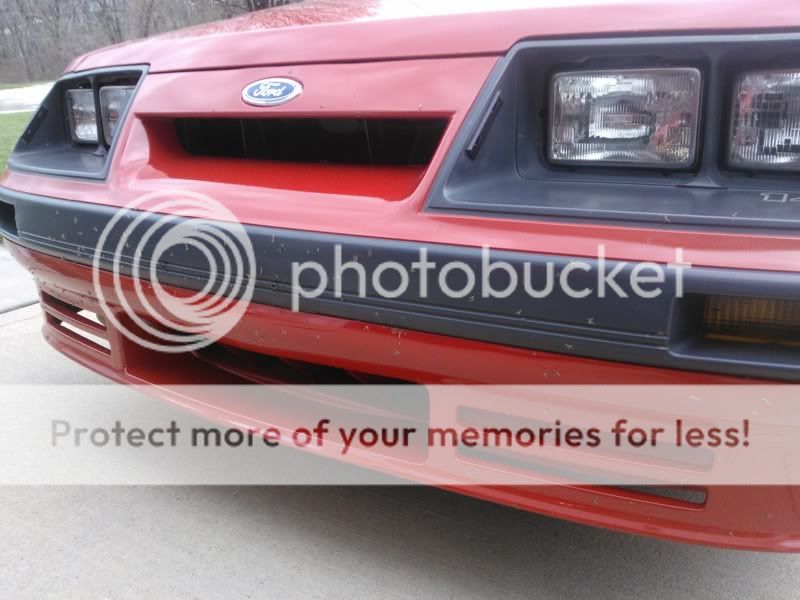

Cleaning! I can't stop once I start... blaming it on the upcoming drive to Knott's...

Cleaning! I can't stop once I start... blaming it on the upcoming drive to Knott's...