Been threatening to do it for a while now and with the rain ruining the days plan decided now would be a good time start this thread. About a year ago my search for an old Ford pick-up came to an end. While I wasn't ready to start a new project just yet the right truck became available so I bought it. Fast forward a year and it's time to start in earnest to build it.

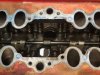

While I didn't do too much actual work on the truck the past year I did do a whole lot of planning. For the longest time, I had planned to use the first engine ('69 302) I built and later pulled out of my mustang in the truck project. The more I thought about it the less that seemed the path I would take. My attention turned to the new 5.0 Coyote platform. Visions of a twin turbo fat fender beast had me going. In fact, I still love that idea...just not for this truck. Maybe the next one. This one is going to keep it's original 8AB flathead V8. For now. Plan is to "hop it up" old school with cam, heads and multi-carb intake. Next year, if I still have the flathead lust, I will build up a new engine top to bottom sporting a polished blower. Already talking with Mike at H&H Flatheads about it now. Thing I've learned about these engines so far is it costs three times as much to make less than half the power. But damn do they look great!

So a little about the truck itself. It was purchased as the owner was nearing the end of a complete stock restoration. An older guy, he had reached the point his health just wouldn't allow him to finish. It had sat for over a year untouched when I found it. The complete chassis was finished and held a running drivetrain. Cab was done and painted bolted in place. Same for the bed. Doors, front fenders, hood, running boards and tailgate were present but needed finish prep and paint. The only thing missing for the entire truck were the rear fenders and the front and rear glass. About as complete as I had found and not a speck of rust on it anywhere. The underside was all in paint and as clean as my car. A true gem.

Since the time I drug it home I have been searching out parts for it. '51-52 are kinda the step child of the Ford trucks. While they reproduce a lot of parts there are some important panels they don't (or didn't). Just recently they started to make rear fenders. A set will cost you about $1500 delivered. And they are Asian made stampings in thinner metal. Hell, any metal is thinner than the stuff they used back in the early Fifties. So long story short, a couple weeks ago I found a set of original rear fenders out in Colorado that a guy had restored for a client that ended up not getting used. A flight, a 14 hour drive and an hour or so roadside chat with the Illinois state police and I had them back home in the garage. Not the cheapest way to go but the best. Now the truck was complete. At least I had all the body panels.

I've also been buying and hording lots of parts for the upcoming build. Namely I scored an original but never used Fenton dual carb intake along with a set of Edelbrock aluminum high compression cylinder heads. Came across the heads in Texas and enlisted my brother who lives in Houston to pick them up. He would later explain to me just how BIG Texas is. I felt bad but hey it was a lot closer than Denver was to Chicago!

The truck came to me with the stock three-on-the-tree transmission. That won't cut it. I'm once again going to rework a T5 trans to put into it. I got a Chevy S-10 T5 tailshaft housing which puts the shifter in a forward position I need to swap out on the mustang unit I have. MDL provided an adapter plate that I can use with an old Ford bellhousing ring called a "hogs head" to mate the T5 to the flathead. I also got a modern clutch set-up from MDL as well. All this is necessary so I can actually drive the truck on the street and not over rev the engine. These old trucks were never meant to go over about 40 mph. Out back I will be swapping in a 9" (originally built for the mustang, again) most likely hung on a 4-link. I'm also adding narrow wheel tubs out back in the bed to allow some really wide tires.

I will be pulling the engine and trans in a couple weeks. Taking off the stock front suspension and installing a whole new mustang II style set-up. Lots of frame work and welding involved. Will also be tearing the engine down for a cam swap and more. I will finally be firing up and using my new TIG welder. Can't wait.

If work and life cooperate even a little I hope to have the truck back on it's own four wheels and operable before winter hits. If I'm really lucky I will get to drive it yet this year before the leaves fall.

So stay tuned if you are interested. I'll be posting up a lot of pics very soon showing the truck as bought, as it sits and of all the goodies on hand so far to get things started. There aren't too many builds going on around here at the moment so this might be fun to watch.

While I didn't do too much actual work on the truck the past year I did do a whole lot of planning. For the longest time, I had planned to use the first engine ('69 302) I built and later pulled out of my mustang in the truck project. The more I thought about it the less that seemed the path I would take. My attention turned to the new 5.0 Coyote platform. Visions of a twin turbo fat fender beast had me going. In fact, I still love that idea...just not for this truck. Maybe the next one. This one is going to keep it's original 8AB flathead V8. For now. Plan is to "hop it up" old school with cam, heads and multi-carb intake. Next year, if I still have the flathead lust, I will build up a new engine top to bottom sporting a polished blower. Already talking with Mike at H&H Flatheads about it now. Thing I've learned about these engines so far is it costs three times as much to make less than half the power. But damn do they look great!

So a little about the truck itself. It was purchased as the owner was nearing the end of a complete stock restoration. An older guy, he had reached the point his health just wouldn't allow him to finish. It had sat for over a year untouched when I found it. The complete chassis was finished and held a running drivetrain. Cab was done and painted bolted in place. Same for the bed. Doors, front fenders, hood, running boards and tailgate were present but needed finish prep and paint. The only thing missing for the entire truck were the rear fenders and the front and rear glass. About as complete as I had found and not a speck of rust on it anywhere. The underside was all in paint and as clean as my car. A true gem.

Since the time I drug it home I have been searching out parts for it. '51-52 are kinda the step child of the Ford trucks. While they reproduce a lot of parts there are some important panels they don't (or didn't). Just recently they started to make rear fenders. A set will cost you about $1500 delivered. And they are Asian made stampings in thinner metal. Hell, any metal is thinner than the stuff they used back in the early Fifties. So long story short, a couple weeks ago I found a set of original rear fenders out in Colorado that a guy had restored for a client that ended up not getting used. A flight, a 14 hour drive and an hour or so roadside chat with the Illinois state police and I had them back home in the garage. Not the cheapest way to go but the best. Now the truck was complete. At least I had all the body panels.

I've also been buying and hording lots of parts for the upcoming build. Namely I scored an original but never used Fenton dual carb intake along with a set of Edelbrock aluminum high compression cylinder heads. Came across the heads in Texas and enlisted my brother who lives in Houston to pick them up. He would later explain to me just how BIG Texas is. I felt bad but hey it was a lot closer than Denver was to Chicago!

The truck came to me with the stock three-on-the-tree transmission. That won't cut it. I'm once again going to rework a T5 trans to put into it. I got a Chevy S-10 T5 tailshaft housing which puts the shifter in a forward position I need to swap out on the mustang unit I have. MDL provided an adapter plate that I can use with an old Ford bellhousing ring called a "hogs head" to mate the T5 to the flathead. I also got a modern clutch set-up from MDL as well. All this is necessary so I can actually drive the truck on the street and not over rev the engine. These old trucks were never meant to go over about 40 mph. Out back I will be swapping in a 9" (originally built for the mustang, again) most likely hung on a 4-link. I'm also adding narrow wheel tubs out back in the bed to allow some really wide tires.

I will be pulling the engine and trans in a couple weeks. Taking off the stock front suspension and installing a whole new mustang II style set-up. Lots of frame work and welding involved. Will also be tearing the engine down for a cam swap and more. I will finally be firing up and using my new TIG welder. Can't wait.

If work and life cooperate even a little I hope to have the truck back on it's own four wheels and operable before winter hits. If I'm really lucky I will get to drive it yet this year before the leaves fall.

So stay tuned if you are interested. I'll be posting up a lot of pics very soon showing the truck as bought, as it sits and of all the goodies on hand so far to get things started. There aren't too many builds going on around here at the moment so this might be fun to watch.