No doubt he is compensating for being friends with a big-eared househusband. He needs all that to try to up his cool factor. I am not sure this is even enough!

Damn Ken, just Daaaaam [emoji38]

Mark

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello there guest and Welcome to The #1 Classic Mustang forum!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

No doubt he is compensating for being friends with a big-eared househusband. He needs all that to try to up his cool factor. I am not sure this is even enough!

Damn Ken, just Daaaaam [emoji38]

Mark

Since I've gone this far, I'll be bodyworking it to make it perfect before it gets sprayed.

Since I've gone this far, I'll be bodyworking it to make it perfect before it gets sprayed.Guess you missed the part where I explained I was simply melting on metal on top of metal to build back some thickness, huh? The pics don't really show how some areas were pretty much paper thin swiss cheese! MIG is the right tool for this one as for once a few "caterpillars" are pretty much just what is needed.That’s some ugly welding. Still haven’t figured out TIG huh?

Mark

I don’t know, let me be clear.

I will be putting a heater in. Mainly for the defrost function for those cool mornings or nights its needed. I have one picked out. It's a small aftermarket piece that I can hide up in the dash neatly. It will allow me to route the necessary hoses out down lower on the firewall, out of sight. It will pain me to drill those holes when the time comes, let me tell you!No heater- I thought you lived in a cold state! Whose bedliner do you use?

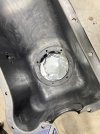

Another project I dove into and completed was the firewall. You'll recall this truck was a running and driving project so it was completely wired up, etc. I have a thing for "less is more" and clean lines so it required the firewall to be stripped clean of everything and all the holes filled and the panel smoothed over. I think I counted in total 73 holes that required filling. Lots of filler patches had to be made. Then there was 70 years worth of minor dings and dents and such to hammer out and smooth over. There were also a few areas where the stamping stretched the metal creating creases and the like. Those had to be addresses too. Anyone who has ever had the pleasure of such an adventure can relate, I'm sure. What many likely think simple ended up taking up all my garage time for the better part of two weeks to get it to where it is today. Worth the effort.

the pics...

View attachment 33696View attachment 33697View attachment 33698View attachment 33699View attachment 33700

Open your ears so you can see better...*G*I’m not seeing the difference.

[emoji12]

Mark