70_Fastback

Hell Bent for Speed

Just a small update; but a useful one for me.

Finally, FINALLY got around to getting new bushings in the spindles and installing the new king pins, bearings, shims etc. The front end is tigheter than a .... well, it's tight to say the least!

And I also made my permanent tie rod in lieu of my damn temporary flimsy conduit tie rod :roul I can now EASILY push it back up the driveway by myself :yah

Since I am doing reversed, or tiller steering (as some call it) I wanted the tie rod to be beefy, but not big and bulky and detract from the front appearance of the setup.

I first decided on 5/8"ID x 5/8"-18 heims/rod ends for the connecting points, which then somewhat determined my tube material. I went with a 1" O.D. - 1/2" I.D. (1/4" wall) DOM tubing.

Raw tubing:

The I.D. had to be drilled from .500" to .578125" (37/64") to facilitate a 5/8"-18 tap. You can see the amount of inner wall thickness being removed. It was finished drilled 2" deep:

And then tapped to 5/8"-18:

Taper the end a bit and install heims joint. Which I found BLACK ones - which is extra cool :yah:

Installed and "home" aligned. Set to 1/16" tow out:

Now, since I am running tiller steering, that means the spindes had to be swapped from side to side -meaning the steering arm would typically extend to BEHIND the axle, not in front like mine is. The main reason is because I did a spring behind setup and the tie-rod would interfere with the spring, shackles, etc. SO, this also messed up which side the leading steering arm went to. The spindles were originally set up for cross steer -meaning the leading arm had two eyelets, which would be on the passenger side. But mine is on the driver side.

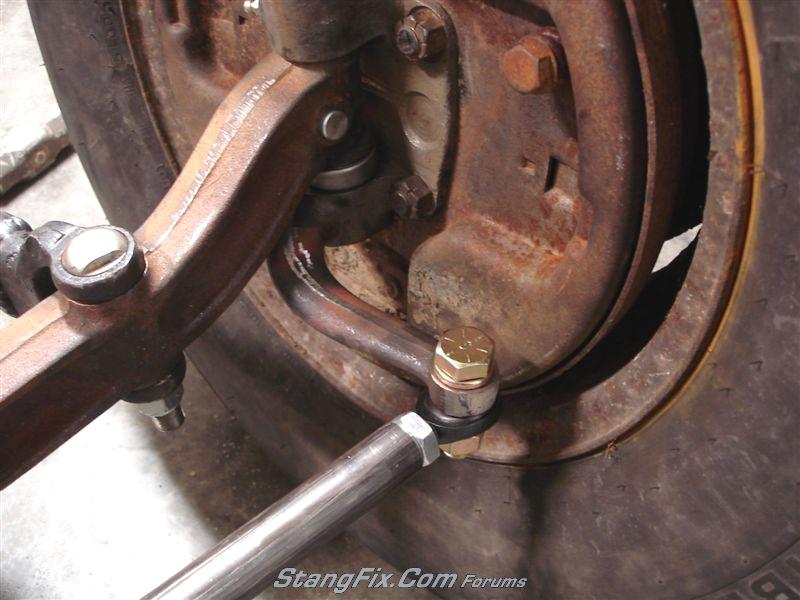

It's hard to see here, but you can see the double eyelet on the end of the driver side steering arm here (it's out in front of the temp tie-rod connection point):

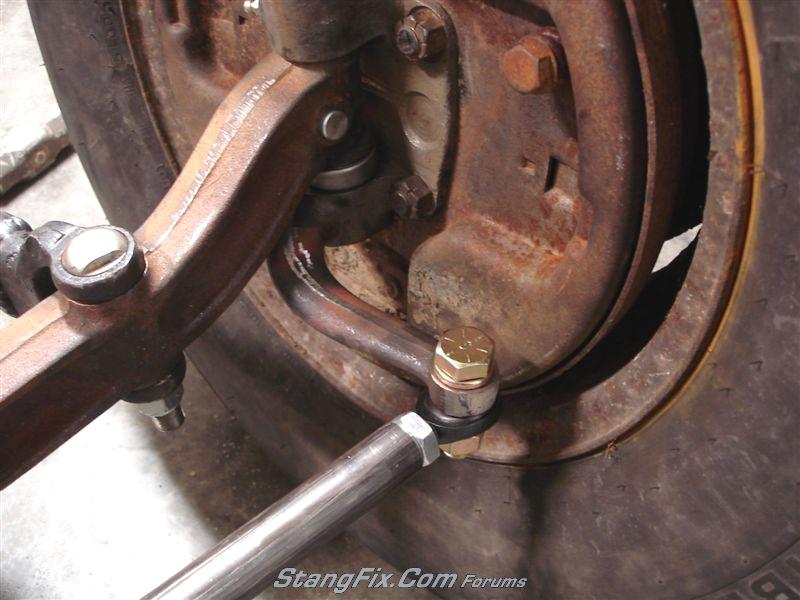

And here is the current driver side arm with that extra eyelet cut off and smoothed. I also had to drill out the tie-rod holes in the steering arm (they where tapered for a standard 1/2" tie-rod end with a tapered shaft. I drilled them out to accept 5/8" grade 8 hardware as well:

Passenger side matches:

Finally, FINALLY got around to getting new bushings in the spindles and installing the new king pins, bearings, shims etc. The front end is tigheter than a .... well, it's tight to say the least!

And I also made my permanent tie rod in lieu of my damn temporary flimsy conduit tie rod :roul I can now EASILY push it back up the driveway by myself :yah

Since I am doing reversed, or tiller steering (as some call it) I wanted the tie rod to be beefy, but not big and bulky and detract from the front appearance of the setup.

I first decided on 5/8"ID x 5/8"-18 heims/rod ends for the connecting points, which then somewhat determined my tube material. I went with a 1" O.D. - 1/2" I.D. (1/4" wall) DOM tubing.

Raw tubing:

The I.D. had to be drilled from .500" to .578125" (37/64") to facilitate a 5/8"-18 tap. You can see the amount of inner wall thickness being removed. It was finished drilled 2" deep:

And then tapped to 5/8"-18:

Taper the end a bit and install heims joint. Which I found BLACK ones - which is extra cool :yah:

Installed and "home" aligned. Set to 1/16" tow out:

Now, since I am running tiller steering, that means the spindes had to be swapped from side to side -meaning the steering arm would typically extend to BEHIND the axle, not in front like mine is. The main reason is because I did a spring behind setup and the tie-rod would interfere with the spring, shackles, etc. SO, this also messed up which side the leading steering arm went to. The spindles were originally set up for cross steer -meaning the leading arm had two eyelets, which would be on the passenger side. But mine is on the driver side.

It's hard to see here, but you can see the double eyelet on the end of the driver side steering arm here (it's out in front of the temp tie-rod connection point):

And here is the current driver side arm with that extra eyelet cut off and smoothed. I also had to drill out the tie-rod holes in the steering arm (they where tapered for a standard 1/2" tie-rod end with a tapered shaft. I drilled them out to accept 5/8" grade 8 hardware as well:

Passenger side matches: