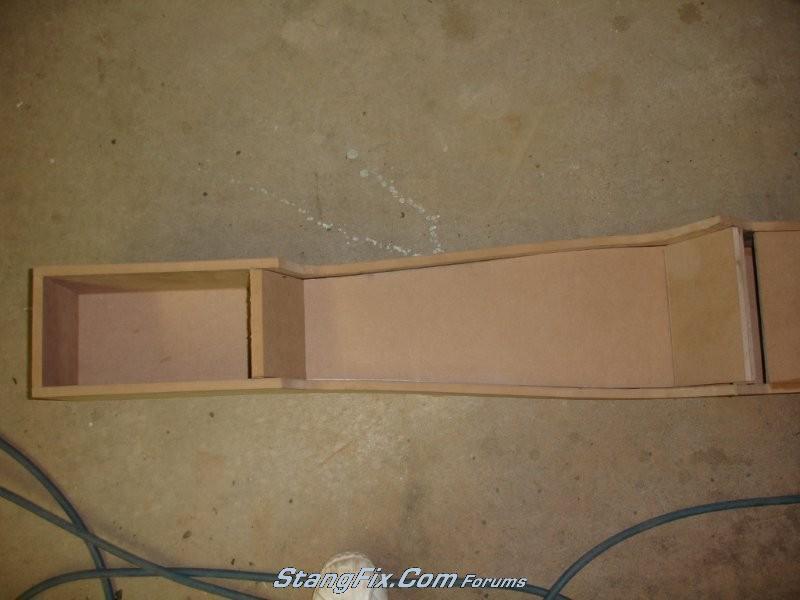

I've made some changes to the original design. So i figured i would start all over. Im pretty happy with this so far. So its a keeper. Today, i started from scratch, so heres the info.

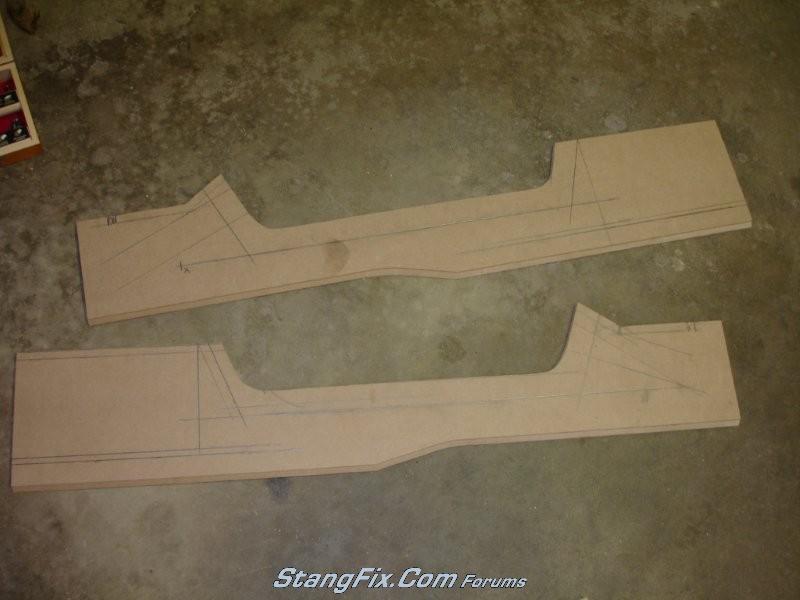

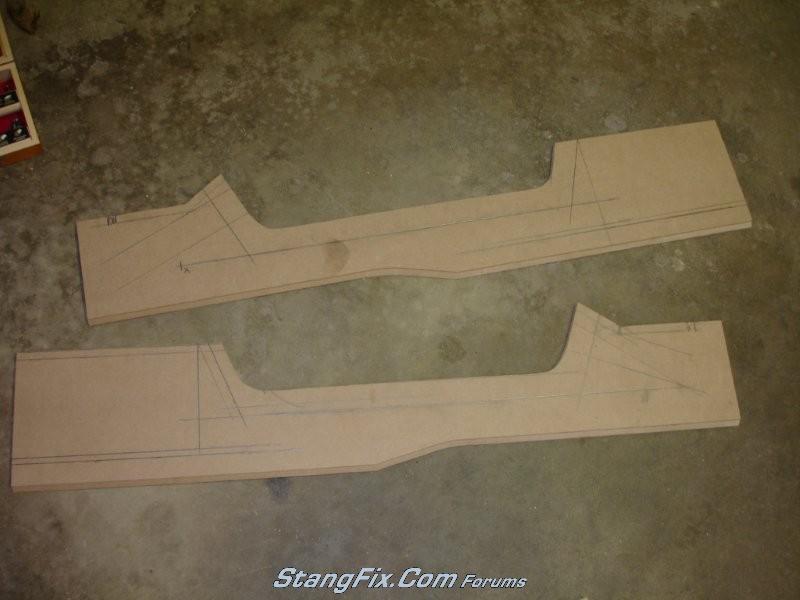

After cutting out two identical sides. I made my marks for assembly. The plan is to wrap these in vinyl to match my interior. By no means do I claim to be a cabinet maker, but I tried my best.

The pencil marks lay out the glove box. The shifter base in the console, and a future opening for gauges. You can also see that i beveled the bottom edge so the console will sit down, and hug the trans tunnel.

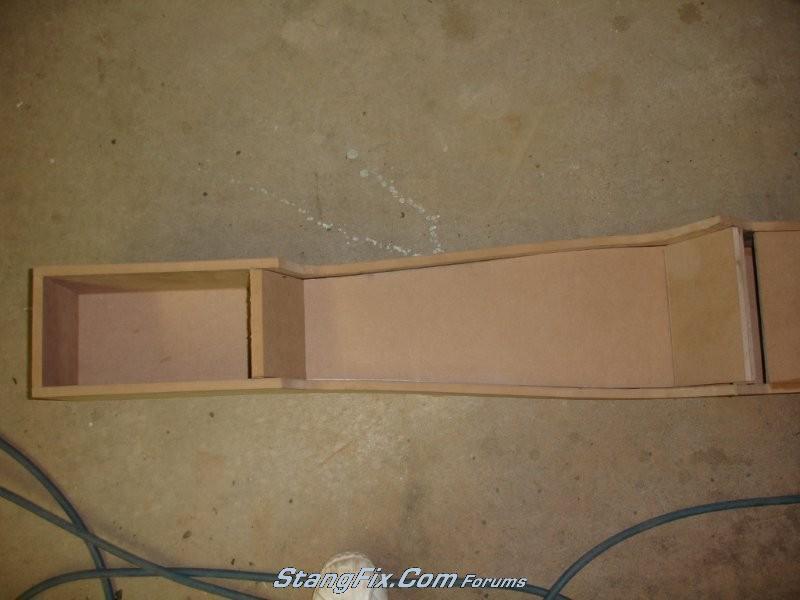

These pieces will soon make up my glove box.

It was assembled using regular yellow wood glue, and 18 gauge 1-[sup]3[/sup]/[sub]8[/sub]" brad nails.

Then clamped tight and the glue was allowed to set.

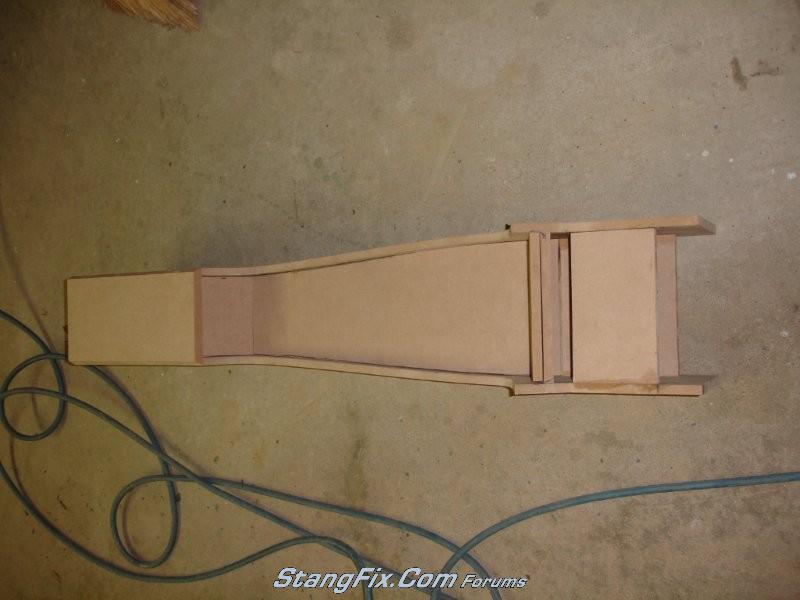

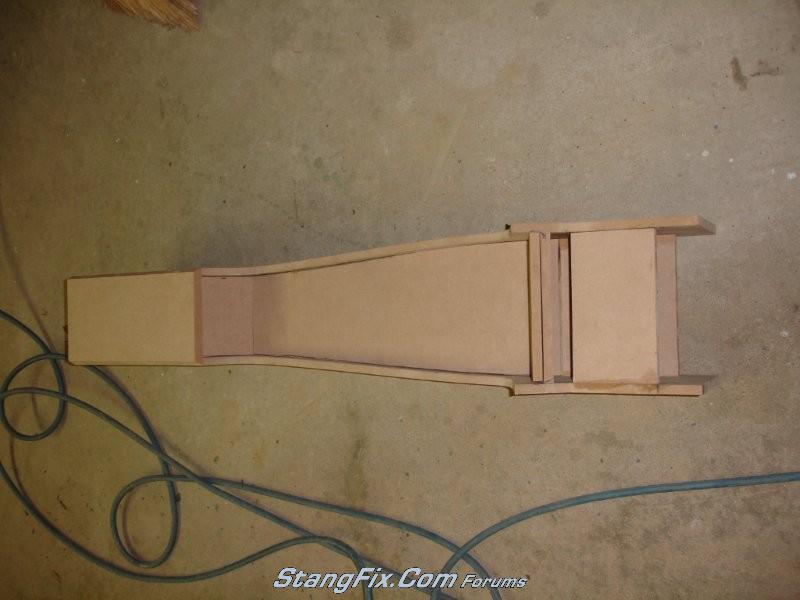

The shifter bezel for the console, was tapered to fit, and then I used a table saw to put two 27 degree grooves 1/2 inch wide to accept the vertical panels.

Im sure a dado blade would have been a lot more efficient, However, i only have the basic power tools.

I then made a lid for the glove box, and tapered the front three edges.

Soon i will seal the MDF (Medium Density Fiberboard), and begin the upholstery process.

After cutting out two identical sides. I made my marks for assembly. The plan is to wrap these in vinyl to match my interior. By no means do I claim to be a cabinet maker, but I tried my best.

The pencil marks lay out the glove box. The shifter base in the console, and a future opening for gauges. You can also see that i beveled the bottom edge so the console will sit down, and hug the trans tunnel.

These pieces will soon make up my glove box.

It was assembled using regular yellow wood glue, and 18 gauge 1-[sup]3[/sup]/[sub]8[/sub]" brad nails.

Then clamped tight and the glue was allowed to set.

The shifter bezel for the console, was tapered to fit, and then I used a table saw to put two 27 degree grooves 1/2 inch wide to accept the vertical panels.

Im sure a dado blade would have been a lot more efficient, However, i only have the basic power tools.

I then made a lid for the glove box, and tapered the front three edges.

Soon i will seal the MDF (Medium Density Fiberboard), and begin the upholstery process.

Last edited by a moderator: